3D4E 3D Printing Design Showcase at USC

We hang out with students from 3D4E to learn about all the awesome 3D printing projects they are working on.

The process of design, testing, and redesign can be daunting. It is a process that is needed more and more as our world moves into an age of technology on par with what was once considered science fiction.

Students from several local schools converged on USC on April 7th, 2018 for the 3D4E (3D Printing For Everyone) Design Showcase at the USC Viterbi Engineering School quad. With three chapters in attendance, USC, UCLA and all the way from Tucson, University of Arizona, there was a lot of hard work and creativity on display.

Each chapter, depending on the number of members, can have a few or several different sub-groups that specialize in a particular area of expertise. The USC chapter has almost 60 members, with quite a few subgroups; education, game design, eNable projects, a drone team, a boat team, and even eyeglasses and medical design!

The newly elected president of the USC chapter, Martin Wolff, was there to walk me through the event and introduce me to all the awesome student participants. The president of the UCLA chapter, Ryan Poon, was also there to highlight the programs his chapter was working on.

The USC chapter has several sub-groups involved with Children’s Hospital LA, mainly in creating low-cost 3D printed hands for children that require hand assistance. Whether the missing hand starts at the elbow or the wrist, the students can customize and create almost anything the child will require. One of the best things about using the open source designs of the eNable Project is the infinite number of customizations you can use to make the prosthetics special for the child. In this case, someone really likes Transformers, and was able to get an awesome, custom Optimus Prime hand!

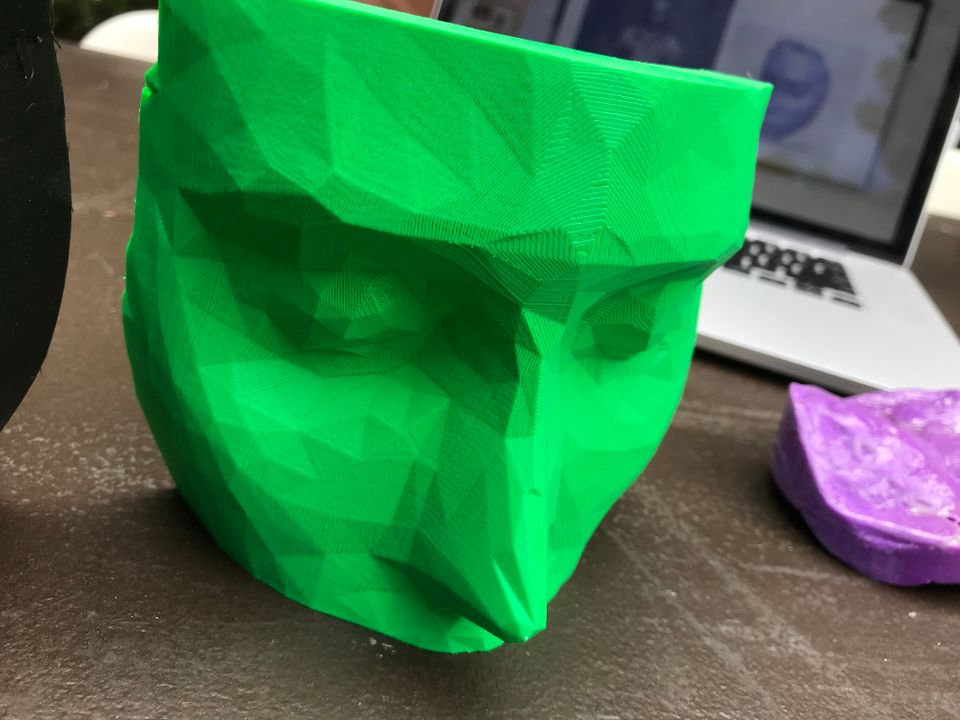

The Bolus team is responsible for coming up with a new way of producing custom pieces for patients to help them in radiation therapy. A bolus is a material which has properties equivalent to tissue when irradiated. It is widely used in practice to reduce or alter dosing for targeted radiation therapy. The bolus team takes this concept to a highly customized level by scanning the part of the patient that is going to receive the radiation therapy, 3D printing a bolus to cover that specific body part with a specific thickness, and delivering the part. As you can see, the face is a perfect demonstration of the capabilities of 3D printing for this application. Each person’s face is different, and the location of the radiation therapy is different in each patient. By using 3D printing to design a customized bolus, each patient’s chance of the therapy working is increased, making treatments even more productive.

The Skateboard Group was busy refining their design to enter into a competition - their invention involved creating a device that attached to the skateboard under the bushings that would alert when the skateboard was being moved without authorization. It includes a Bluetooth module to alert the owner on their phone, and it also makes a loud, piercing noise to deter the thief once the skateboard is moved! Genius!

The Education Team is responsible for producing materials to help students increase their abilities to learn using visual and tactile methods. While some students are fine with traditional reading and note taking methods for learning, some students learn best when they can manipulate the information they are trying to learn. With custom, physical models that have been 3D printed for lesson plans, students are able to increase test scores, and are more likely to retain the information they are learning. While geography and chemistry are shown here as examples, custom 3D printed educational materials can be used in any subject to help tactile learners.

One of my favorite groups was the Art Group - they were busy on the seventh or eighth iteration of a ukulele they were designing to deliver to a local orphanage for children. The process of making the instruments involved making sure they created a good tone while being played, could be used like a traditional ukulele especially in regards to the fretboard, and include specific hardware for holding and tuning the strings. They had originally envisioned creating toys for the children, but decided on ukuleles because the children would get much more benefit from learning to play their own instruments.

In addition to these groups, there was a group that concentrated on creating eyeglasses using magnets for the hinges to hold the temples to the eyewires. There was also a Map Group which has already designed a 3D printed model of the USC campus. There is also a Drone Group, a Boat Group, a Game Design Group, a Acetone Vapor Bath project, and so much more.

It was truly inspiring to see so many students working on solutions to problems using 3D printing. The passion and excitement they have for their endeavors was awesome, and I can’t wait to see what they come up with in the coming year.

Thanks to Martin, Ryan, and all the amazing 3D4E students working on making the future a better place for the world!

If you or someone else you know is using 3D printing in education and would like to have a story featured on our website, please send an email to chris.morgan@matterhackers.com - we would love to hear from you!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.