How To: Troubleshoot a TAZ 6 Leveling Error

Sometimes, systems in place to make 3D printing easier just ends up making things more difficult. Here's a couple tips to help your Lulzbot finish its leveling routine without error.

At MatterHackers, we need a lot of printing assets for one reason or another. Whether it’s for a new video, posts for social media, or just a cool project we want to get done, there are a lot of printers at my disposal to get it done. When I need something large, I’ll usually go for the Lulzbot TAZ 6 due to its sizeable build volume. But sometimes the bed leveling procedure fails and there isn’t a way to manually level the bed and disable the bed leveling, but there is a solution.

Note: as the Lulzbot Mini uses the same leveling system, this solution equally applies.

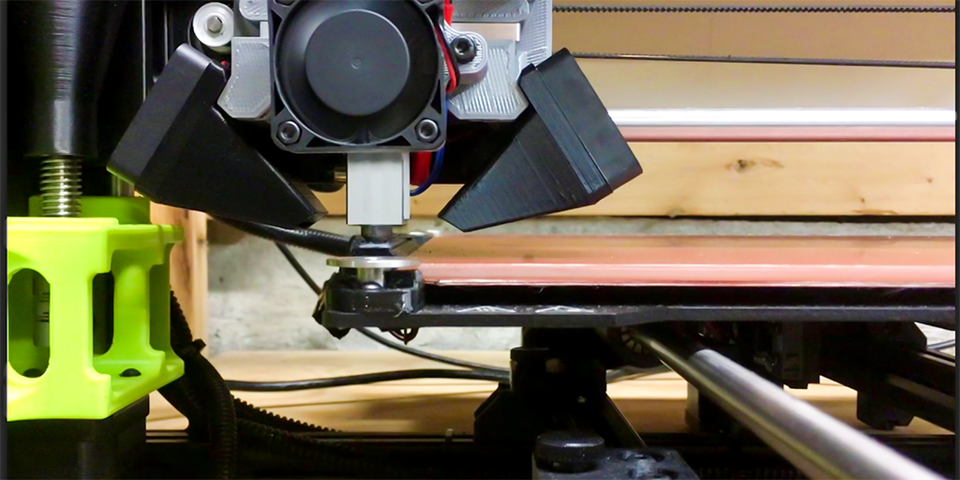

First off, let me explain how the Lulzbot TAZ 6 levels the bed: there is a wire that runs from the board to the heater block, where it is mounted using a small screw, and another set of wires that run from the board to each of the four washers that clamp onto the bed. Before each print, the Lulzbot wipes off the nozzle on a small cleaning pad, and then will quickly probe one corner, move away from it, and come at it again slower. Once it taps the washer the second time, it moves onto the next washer until all four have been probed.

Now because it has to close a loop, it needs to make electrical contact, and if there is any burnt or stuck filament on the tip of the nozzle, no matter how hard it presses into the corners it won’t close the circuit and register it as a failed probe.

If your Lulzbot TAZ 6 or Mini has a failed probe cycle and it’s clearly making contact, the following techniques and steps should be kept in mind. If the nozzle doesn’t reach the bed and that’s causing the failure, make sure the X axis is square with the Z axis.

To solve this, all you need to do is measure from the top of the X axis rods to the top of the printer frame, and if they don’t match, turn off the printer and manually turn the threaded rod of one of the Z axes until they do. This should solve the issue for you, but if even that doesn’t work, check to make sure that the bed doesn’t have a lot of play. If the IGUS bearings on the Y axis are really loose against the rods, it may be time to perform some maintenance and replace them, as this would shift the plane the bed and Y axis is on.

To fix a failed bed probe, you’ll need a couple tools on standby:

- A spatula,

- Tweezers or needlenose pliers

- A wire brush.

Method 1:

- Raise the Z height of the print head until there’s enough room to fit the wire brush beneath the tool head, 100mm should be enough.

- Heat up the hotend to 260C to soften any material that may still be on the nozzle.

- Use the wire brush to clean off all the gunk.

This is more aggressive than the pad that the Lulzbot wipes on, so you may have more luck getting this to clean off dirty nozzle than the standard way,

Attempt 2:

- Raise the Z height of the print head just enough to fit a spatula under the nozzle, 50mm should be plenty.

- Use the flat face of the spatula to rub the tip of the nozzle until the metal shows through again.

This is the “brute force” option between the two; rather than cleaning the entire nozzle with a normal tool, you’re just trying to clear out just enough to make the tip make contact and connect with the washers.

Whether you’re using Method 1 or Method 2, be sure to really clean off the washers as well. Both Lulzbot printers will probe in roughly the same spot, so it may deposit some melted plastic as it’s failing to register its probe, making each subsequent probe fail no matter how clean the nozzle is.

I hope this helps improve your experience with the Lulzbot TAZ 6 or Lulzbot Mini; such a small error can throw a wrench in any printing schedule, so it helps to have more techniques in your back pocket.

Happy printing!

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.