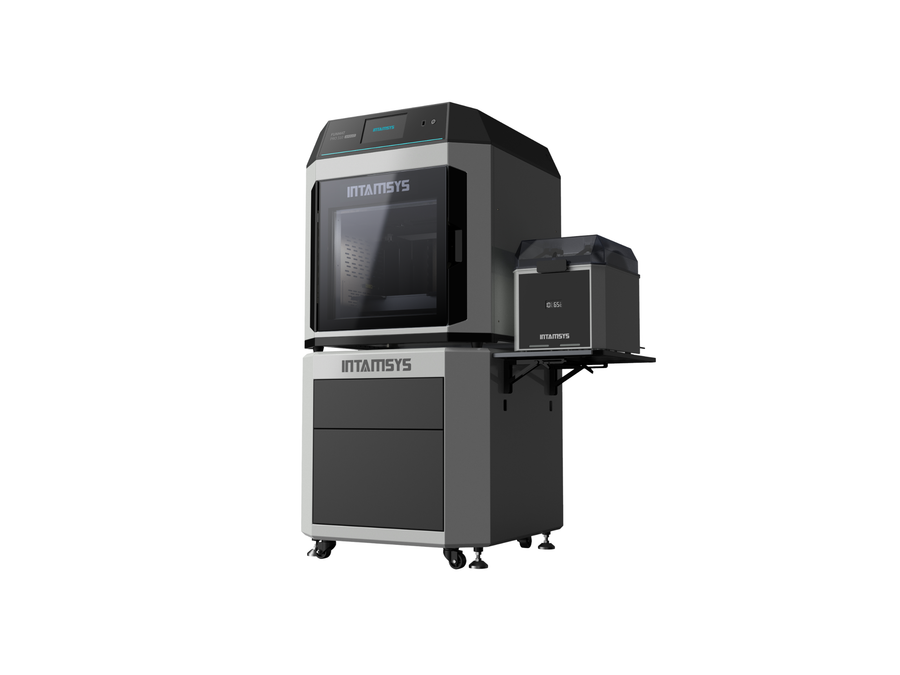

Intamsys Intamsys Funmat Pro 310 Apollo 3D Printer

The Funmat Pro 310 Apollo is an industrial IDEX 3D printer for production-grade PAEK parts. It prints the full PAEK family with dual independent extruders reaching 200 mm/s and includes a 3 kg active-drying filament box plus INTAMQuality data tracking for continuous, traceable production.

- Produce PAEK end-use parts at validated 200 mm/s speeds

- Ensure full-process traceability and remote batch quality monitoring

- Sustain uninterrupted multi-day production of high-temperature PAEK components

| List Price: | $17,000.00 |

|---|---|

| Price: | $17,000.00 |

| Price: | $... |

| Order Now: | Processed Immediately Ships via Freight - some fees may apply. |

Intamsys Funmat Pro 310 Apollo 3D Printer

Industrial IDEX 3D Printer for PAEK Production

The Funmat Pro 310 marks a new era of industrial-grade FFF 3D printing, combining high-performance materials, ultra-fast printing, and production-level consistency. From PEEK prototyping to PAEK end-use part manufacturing, INTAMSYS redefines FFF performace and reliability.

Key Features of the Intamsys Funmat Pro 310 Apollo 3D Printer:

- High Performance Material Printing: Supports the full PAEK family with reliable mechanical performance under high temperature and load-bearing conditions.

- High-Speed Printing System: Dual independent extruders optimized for PAEK achieve speeds up to 200 mm/s, 4x faster than other printers. Offers exceptional speed and mechanical strength that enables efficient production.

- Continuous Production Solution: 3 kg active-drying filament box and INTAMQuality data tracking are included, allowing for continuous manufacturing, full traceability, and consistent high-temperature performance.

- Intelligent Control Platform: INTAMSUITE Neo integrates multi-physics, control of temperature, flow, and path for smart monitoring and remote management.

Faster, Strong, and More Reliable

Achieve high-performance batch production with materials and systems designed for strength, speed, and consistent scalability. Ensure dependable output, streamlined workflows, and quality you can trust from print to end use.

- Strong, application-ready parts with uninterrupted printing performance

- Faster production to maximize ROI and accelerate end-use delivery

- Scalable, traceable, and automated processes for reliable quality assurance

High-Temperature Stability

Engineered for reliable performance with advanced hardware and software tailored to PAEK materials. Delivers consistent thermal control to improve precision, repeatability, and overall print success.

- Optimized system design for high-performance PAEK printing

- Stable chamber temperatures up to 100°C for consistent results

- Reduced warping and material variability for dependable part quality

Built-In Traceability

Integrated quality monitoring ensures full visibility throughout the entire print process. From material verification to final validation, every part is tracked with confidence.

- Real-time data logging powered by the INTAMQuality system

- Complete part tracking and material traceability

- RFID-based spool recognition for accurate material management

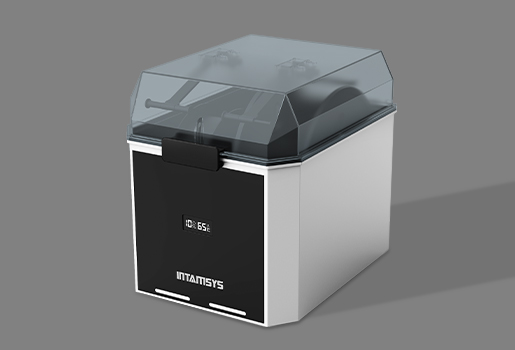

INTAM Box

Included is the INTAM Box, a filament storage and dryer solution that holds 2 x 1 kg / 2 x 3 kg spools in independent and sealed chambers with automated spool recognition and dual-spool feeding. Features dual-channel heating, real-time temp & humidity monitoring, and anti-tangle, user-friendly design.

- Holds 2 spools per chamber with automated recognition & feeding

- Dual-channel heating up to 65 °C with real-time temp & humidity monitoring

- Anti-tangle design with safety warning lights for hassle-free printing

Double the Output

|

||

| The Independent Dual EXtrusion System doubles PAEK output further, achieving 8x faster than traditional printers. |

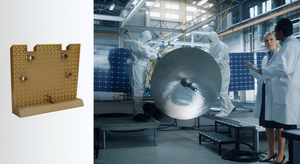

Targeted Industries and Applications

Aviation |

Aerospace |

|

Interior components, brackets, ducts,

|

Sensor brackets, antenna reflector &

|

Robot-Manufacturing |

Oil & Gas |

|

Bearings, gears, joint links, reducer

|

Valve bushings, seals, pipe fittings, pump

|

| Medical | Automotive |

|

Surgical guides, denture bases, |

High-temperature engine components |

| Manufacturing | and more... |

|

Customized tooling fixtures, valve |

|

What's Included

- 1 x FUNMAT PRO 310 APOLLO 3D Printer

- 1 x INTAMBox (3 kg Capacity)

- 1 x INTAMQuality (1 year license free)

- 1 x Material Package

- 1 x PEEK (1.75mm, 1 kg, natural)

- 1 x SP5080 (1.75mm, 1 kg, natural)

- 1 x ABS-HS (1.75mm, 1 kg)

- 1 x HIPS (1.75mm, 1 kg)

- 2 x High Temperature Printhead (for PAEK materials)

- 2 x Normal Printheads (for Engineering materials)

- 1 x Mangetic Thickened Hardened Buildplate for PAEK materials (HPP Buildplate)

- 1 x Magnetic Flexible Buildplate for Engineering materials (EP Buildplate)

- Other tools and spare parts

Technical Specifications of the Intamsys Funmat Pro 310 Apollo 3D Printer

| Printing | |

| Technology | FFF (Fused Filament Fabrication) |

| Build Volume | Single Nozzle: 305 x 260 x 260 mm Dual Nozzle: 260 x 260 x 260 mm |

| Layer Thickness | 0.1 - 0.3 mm |

| Number of Nozzles | 2 (IDEX) |

| Nozzle Temperature | Max. 450°C |

| Printing Speed | Max. 500 mm/s PAEK Max. 200 mm/s |

| Printing Acceleration | Max. 8000 mm/s |

| Chamber Temperature | Max. 100°C |

| Platform Temperature | Max. 160°C |

| Leveling | Mesh Leveling (Max. 100 points) Dual-extruder auto calibration |

| Filament Diameter | 1.75 mm |

| Materials* | PEEK, PEEK-CF/GF, PEKK, VICTREX AM 200 FIL, VICTREX AM 450 FIL, PC, PC-ABS, PC-FR, ABS-HS, PPA-CF/GF, PA6/66, PA12, ASA, PPS, PPS-CF/GF, and various fiber-reinforced and support materials |

| Functions | Nozzle clogging alarm, platform over-temperature alarm, filament run-out detection, printing recovery from power loss, remote monitoring, remote control, remote printing, software and hardware OTA, filament auto-loading, material identification, auto-cleaning nozzles, INTAMQuality |

| Machine | |

| Voltage | 100 - 120V/16A or 200 - 240V/8A 50-60Hz |

| Max. Power | 1800W |

| Connectivity | WiFi, Ethernet, USB |

| Screen | 7-inch Touch Screen |

| Build Plate | Magnetic thickened hardened buildplate Magnetic flexible buildplate |

| Build Chamber | Fully enclosed heated chamber |

| Nozzle Maintenance | Modular design for fast maintenance and quick replacement |

| Cooling | Fan |

| Filament Box | 3 kg sealed chamber with reusable molecular sieve, real-time temp / humidity monitoring, and 65°C internal heating |

| Number of Spools | 2 (Max. 3 kg/pcs) |

| Resolution | XY : 16 μm, Z: 1.25 μm |

| Filtering System | HEPA + Activated Carbon, Replaceable |

| Overall Dimensions | 700 x 655 x 750 mm |

| Safety | |

| Safety Design | Safety door lock, over temperature protection, overload protection, warning labels |

| Slicing | |

| Slicing Software | INTAMSUITE NEO |

| Supported File Type | .stl / .3mf / .obj / .x3d / .g / .oltp / .stp / .step / .iges |

| Operating System | Windows 10 / 11 |

| Operating Environment | |

| Working Temperature | 0°C ~ 30°C (32°F ~ 86°F) |

| Working Humidity | 20 % ~ 70% |

| Storage Temperature | -20°C ~ 55°C (-4°F ~ 131°F) |

| Storage Humidity | 10% ~ 90% |

* Printing Materials are not limited to this table, recommended printing materials are fully validated on the printer.