MakerBot Nylon-12 Carbon Fiber 3D Printing Filament

With MakerBot's combination of carbon-fiber nylon-12 filament and affordable 3D printing, users have greater access to more options for industrial-grade production than ever.

MakerBot Nylon 12 Carbon Fiber is a new carbon-fiber nylon filament that gives superior results for high-performance 3D printing. When used properly, the tensile strength and superior heat deflection of this material will give users added benefits in the longevity of the print, as well as speed to production from lower print-fail rates, and an increase in their bottom line from less wasted filament.

Nylon has been in use as an industrial material for almost one-hundred years. Initially seen in use for manufacturing in the textile industry, nylon has been adopted by a growing number of industries, including fashion, automotive, aerospace, electronics, and more due to its favorable properties. Depending on the manufacturing method and design, nylon can be extremely rigid or flexible, it has an extremely low friction coefficient, and it has very high tensile strength.

Until recently, nylon was confined to the factory floor as a mass-production manufacturing material. Now, nylon is available to the small business and home consumer as a 3D printing filament. Advances in production have made it more accessible for anyone to use in almost any 3D printer that can attain around 260 degrees Celsius in the printer’s hotend. Along with advances in nylon materials, users also have access to garolite as a print bed surface - a superior adhesive for nylon, and when used with a simple glue stick as a release agent, warping is extremely rare, making printing success likely for all users.

One small issue for nylon filament is its tendency to absorb moisture from the air. This hygroscopicity means that nylon should be dried immediately before, and during longer print jobs, to avoid inconsistent layer adhesion on prints. There are several accessories available on the market to help users avoid this issue, including the Print Dry Filament Drier. One of the distinguishing factors of MakerBot’s Nylon-12 is the lower rate at which it absorbs moisture from the air. This means less drying time and less chance of a failed print.

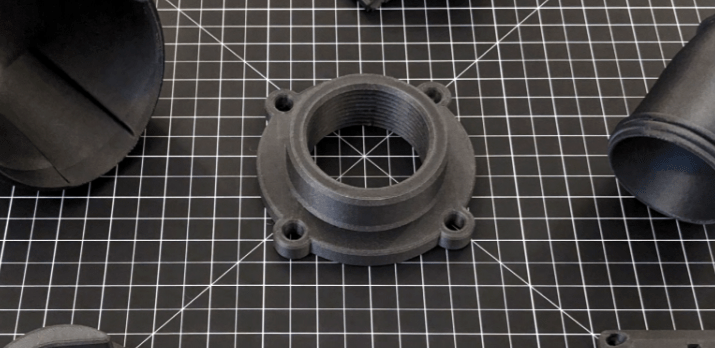

Nylon is similar to ABS in mechanical properties, with the advantage of being more resistant to wear and fatigue, as well as being more flexible when printed thinner in various designs. Adding carbon-fiber particles to nylon turns an already remarkable material into a true powerhouse for small-scale manufacturing. This addition allows printed objects to have superior capacities for carrying prolonged loads, higher impact-resistance, greater abrasion resistance, as well as increased stability and rigidity.

The addition of the carbon-fiber also decreases the possibility of warping, making it easier to print than standard nylon filament. Nylon carbon-fiber prints also come off the print bed with an amazing matte finish that requires little to no post-processing for print-ready parts.

With the combination of carbon-fiber nylon filament and affordable 3D printing with the awesome line-up of MakerBot Method and Method Carbon-Fiber 3D printers, users have greater access to more options for industrial-grade production right at home, and for their small and medium-sized businesses.

To shop for MakerBot Carbon Fiber 12 Nylon, follow this link:

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.