MakerGear Wins Air Force Challenge with Budget-Friendly 3D Printer and PLA

USA-based 3D printer manufacturer MakerGear won First Place in the Advanced Manufacturing Olympics held by the US Air Force Rapid Sustainment Office (RSO) with the most common 3D printing material - PLA.

From October 20th to 23rd, 2020, a (virtual) challenge unlike any other was issued by the United States Air Force Rapid Sustainment Office (RSO) with teams competing to win nearly $1,000,000 in prize money. The first annual Advanced Manufacturing Olympics consisted of five separate competitions; The TDP (Technical Data Package) Relay, the Box of Parts Floor Exercise, Material Hurdles, Approval Sprints, and the Supply Chain Marathon.

- Box of Parts Floor Exercise: Teams were to demonstrate 3D scanning and printing technology’s ability to accurately re-engineer a part without an existing plan. With the rise of handheld scanning, the end goal was to identify automated or hands-free scanning for rapid and accurate reverse engineering capabilities.

- Material Hurdles: Test the strength of materials, ingenuity of design, and ease of use of proposed solutions. The goal of this technical challenge was to identify and demonstrate new aluminum materials that will further the AM industry.

- Approval Sprints: Identify innovative strategies for rapid design, qualification, and deployment of sustainment solutions which leverage new manufacturing materials, processes, and components.

- Supply Chain Marathon: Develop the use of novel advanced manufacturing concepts coupled with innovative Supply Chain Management (SCM) approaches to propose the best-basing strategy that satisfies the most warfighter requirements and delivers parts on-time and on-schedule.

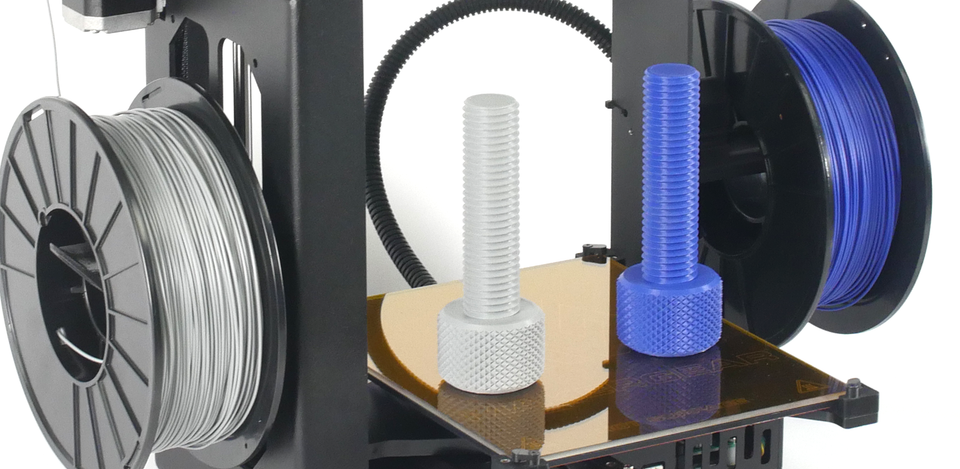

The Technical Data Package Relay challenged 13 teams across the US to accurately recreate a 3D-printed part from an existing Technical Data Package using innovative techniques while demonstrating accuracy, skill, and completeness. MakerGear, a 3D printing manufacturer based in Beachwood, Ohio stepped up to the plate and hit a home run with their award-winning M3 3D printer and simple, natural PLA filament. Compared to other competitors, MakerGear came into the contest using the most common filament, and the most basic 3D printer. Other teams utilized machines that cost upwards of fifteen thousand dollars and used materials that are unavailable to the average consumer due to their extremely high cost.

The 13 competitive teams were sent an STL with specific expectations for tolerances. The part needed to withstand 10psi of pressure and 200lbs of weight. The competitors brought a full range of options to their parts, including innovative print orientations for increased strength, and materials like ABS, Polycarbonate, Kevlar, and Carbon Fiber composites with PETG or Nylon. Even resin with added graphene was submitted for testing. 3D printers also varied from the MakerGear M3 up to a MarkForged 3D printer and even a Stratasys Fortus 450.

“As 3D printing technology is advancing extremely quickly...we want to be sure we can still use the (polymer) printers we have,” explains Lily Arcusa, Chief Technology Officer and Director of Engineering for the Air Force Rapid Sustainment Office. “The primary goal (of the TDP Relay) is to understand how to get into individual settings on a printer...to be able to understand which settings are creating the characteristics and properties we need, and then replicate those on a different machine...to print an equivalent part without having to start from scratch.”

MakerGear did their own testing before deciding on PLA as their final material. They printed test coupons in ABS, PETG, Nylon with Carbon Fiber, and other materials before finding that natural PLA held the most weight by far - up to 400lbs in their final test! Pollack was especially happy with these results for the Air Force, as PLA is the most widely available material, the easiest to print, nontoxic, and very inexpensive. After testing different layer heights, cooling settings, and print temperatures, they printed their part with a 1.75 nozzle at 200-micron layer height. The part was submitted with no additional post-processing - just straight off the MakerGear M3.

MakerGear was close to not being in the competition at all; MakerGear CEO, Rick Pollack, explains, “We found out about the AMO just a day before the application deadline and did not fully appreciate the magnitude of the opportunity when we applied for the Technical Data Package (TDP) Relay. A few weeks after applying, we received notice that we'd been accepted and then a few weeks later there was a virtual kick-off event where we learned the details of the challenge.”

After being told that their submission achieved “almost unanimous perfect scores,” MakerGear was awarded the gold medal, along with the $100,000 first prize. When asked if they will be back to defend their title next year, Pollack replied, “Count us in!”

The challenge was based on the needs encountered by the Air Force, and other Armed Forces branches, as they work on updating and repairing legacy aircraft and weapons systems. The RSO designed the TDP and the other challenges to address pressure points of their production and supply chain management by creating competitions based around these problems and turning them into innovative opportunities for outside agencies. The AMO was originally envisioned as an in-person event that would have taken place in Salt Lake City were it not for the pandemic. Luckily, the AMO team was able to transform the event into an online juggernaut, bringing competitors from all around the world together in true Olympics fashion.

One of the primary considerations for holding a competition like this is to invite companies like MakerGear to showcase not just machinery, but the innovation of personnel as well. The Department of Defense currently relies on public and private partnerships with civilian and private tech sector companies to foster ideas that will give the United States more resources in humanitarian aid and combat capabilities.

As many deployments are nowhere near a manufacturing facility or a convenient shipping location, the military has come to rely more and more on additive manufacturing to provide for the needs of these remote troops and their equipment. The SRO focuses on maintenance of aging transport, and most of their conversations are around how to scan and remotely produce parts with high strength and tight tolerance for emergencies, often in the middle of a jungle or desert - this has led them to look increasingly at the capabilities of 3D printing.

Because private-sector tech companies are in the business of driving innovation in new and imaginative ways, they have become a natural recruiting point for people and ideas. But sometimes a solid, reliable approach also works. Rick and his team feel their win was in part because of their ‘ground floor’ approach. “The ideation of any part, whether it’s a new or a replacement part, is to iterate it into being. You have to start with that idea, and in our case, we were able to hit the ground running with the information contained in the TDP challenge materials, and get it in hand as soon as possible. With 3D printing, that means PLA for the material and fast, simple printer settings. If we get the object into reality quickly, we are able to make changes and iterate on the things that will make it work even faster.”

For more information on the winning MakerGear M3 and selections of PLA, check out MatterHackers.com, or contact sales@matterhackers.com for GSA contract pricing. Learn more about the RSO at www.afrso.com.

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.