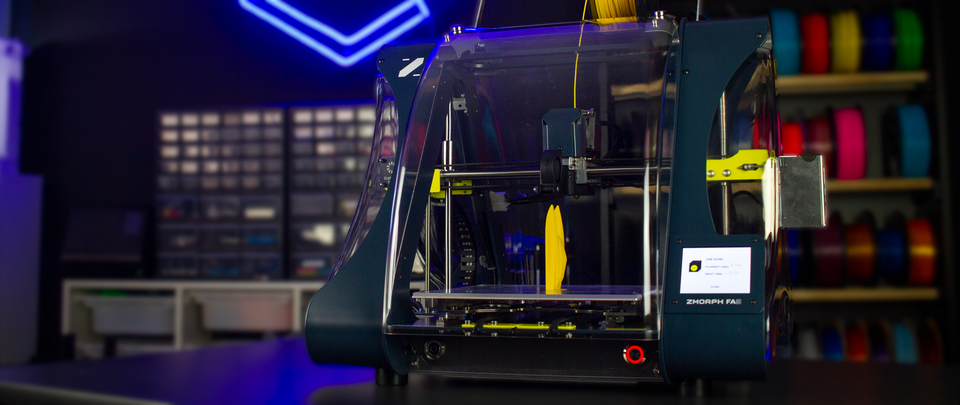

Tech Breakdown: Zmorph FAB All-In-One 3D Printer Review

The latest machine from Zmorph is more than just a 3D printer, it's a full-fledged workbench in one platform.

Outfitting a workspace with new tools can be challenging; you want to make sure you have everything you need, but sometimes you’re limited by the space available. The Zmorph solves this problem by being an all-in-one manufacturing platform. This combination 3D printer and CNC mill can turn the smallest desk into a full-fledged workbench, all while being a safe and reliable piece of equipment packed full of features that raise the bar for the desktop manufacturing industry.

Let's break it down-

Turn Your Desk into a Workbench

The signature feature of any Zmorph 3D printer is the all-in-one functionality and the Zmorph FAB is no exception. With its quick-change toolheads, you can outfit your desk with an entire workshop in one package.Each of the toolheads easily integrates into the platform without the need for tinkering or disassembly. Simply undo a couple screws, unplug the wiring, slot in the new toolhead, plug it in, lock it down, and the Zmorph FAB will automatically detect and calibrate the new hardware. When you need a machine that can do it all, the Zmorph FAB should be first on your list.

Safe, Reliable, and Hassle-Free

Every part of the Zmorph FAB has been inspected and tested for the ultimate performance, no matter the type of job. The 3D printing head has autocalibration for leveling the bed to make setup quick and easy, even for beginners. Any CNC mill necessitates rigidity for peak performance, and the heavy-duty aluminum plates that make up this machine’s frame provide that rigidity, along with keeping the electronics safe from dust and debris from CNC machining. To keep the air around the enclosed build chamber clean and safe, a combination HEPA/carbon filter removes any potential particles and fumes from the air, a handy safety measure for 3D printing or milling inside an office or classroom.

Fully Featured

From top to bottom, the Zmorph FAB is equipped with all the features you need and even those you didn’t know you wanted. Just like the machine, the Voxelizer software is an all-in-one package that prepares your files for 3D printing and CNC machining. This makes it quick and easy to start up with any toolhead. When you’re ready to 3D print, the heated bed can reach up to 115°C for the most demanding materials you can work with. Unique to the Zmorph FAB are the closed-loop motors, which are capable of detecting any skipped steps and correcting it, which means if anything goes awry during your projects, the motors will help get you back on track. And it’s a good thing the Zmorph FAB’s abilities grab your attention, otherwise, its ultra-quiet stepper motor drivers might have made it hard to notice.

When you need to make the space you have in your workshop and your wallet count, an all-in-one solution like the Zmorph FAB is the sensible choice. To learn more about the Zmorph FAB and its many toolheads and to order yours today, check it out here.

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.