What is 3D Printing?

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

What is 3D Printing?

3D printing, which is also known as additive manufacturing, is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

What Types of 3D printing are there?

There are two main types of 3D printing:

- Fused Deposition Molding (FDM)

- Stereolithography (SLA)

FDM 3D printing is also known as fused filament fabrication (FFF 3D printing), and it is the process where thermoplastic 3D printing filament is extruded through a heated nozzle that melts the plastic, allowing it to follow the path of your digital file layer-by-layer until your object is complete.

SLA 3D printing is the process where liquid resins are cured or hardened layer-by-layer using a laser, LCD screen, or digital light projector. Once an SLA printed part is complete, it must be post-processed in UV light.

What is the Best 3D Printer?

There are hundreds of 3D printers to choose from - which one is the best? Finding the best 3D printer entirely depends on what you want to make with your 3D printer, and of course, your budget. Do you want to 3D print big parts or small parts? Do you need to print strong, functional parts, or are you more interested in making models that won't need to be strong? Do your 3D printed parts need to be as clean and detailed as possible, or do you need them to just be functional with little detail? Every 3D printer has different characteristics that will determine which is the best 3D printer for you. If you need help deciding on which 3D printer is the best, contact sales@matterhackers.com and we can help walk you through the hundreds of options available at MatterHackers.

How Much Does a 3D Printer Cost?

A desktop 3D printer costs anywhere from $165 to $12,500. 3D Printing has become more accessible over the years as more options have become available in a wide price range. You can shop all our 3D printers here.

Is 3D printing hard?

No, 3D printing is easy to do! With the right tools and guidance from the experts at MatterHackers, you can learn to 3D print easily. Check out our article on the Top Ten Tips When Getting Started With 3D Printing and you'll be on your way to 3D printing like a pro in no time.

Is 3D printer filament expensive?

No, 3D printer filament is not expensive. You can find base materials like PLA, ABS, and PETG for as low as $15.68 per 1kg spool, like our MH Build Series filament.

You can even print with real stainless steel metal on any desktop 3D printer for as low as $129 per 1kg spool, which in the world of metal manufacturing is an incredible rate that is much more efficient than traditional metal machining methods.

More advanced materials can be a little steeper in price based on the materials that they are made from, but all-in-all 3D printing is an incredibly cost-friendly way to create custom parts and products. You can browse all 3D printer filament here.

Is 3D Printer Resin Expensive?

No, 3D printer resin is not expensive. You can find 3D Printer resin for as low as $15.97 per 500g bag, like our MH Build Series Resin.

Premium resins that are made for specific applications can be a little more expensive than average model resins. However, 3D printing is still a more affordable way to manufacture parts or create models when compared to traditional methods. You can browse all 3D printer resins here.

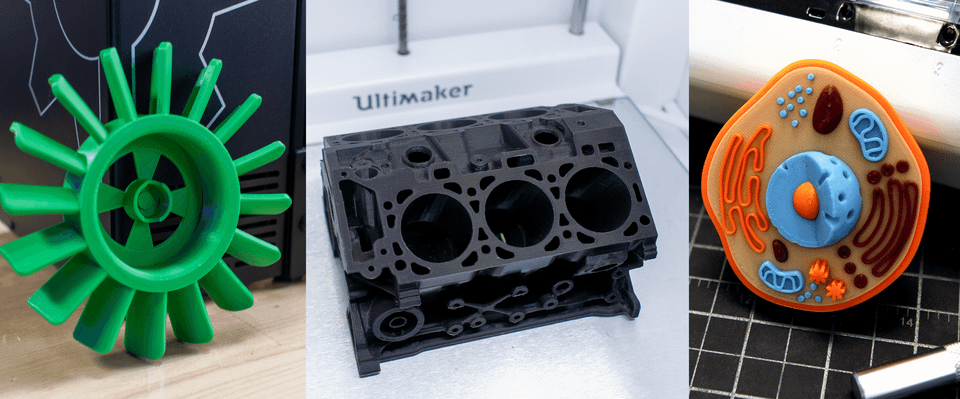

What Can a 3D Printer Make?

You can make nearly anything with a 3D printer. Many industries use 3D printers for rapid prototyping, manufacturing functional end-use parts for products, or even custom jigs and fixtures. 3D printers can also be used in the home for creating fun items, things that break around the house, or even cookie cutters. With 3D printing, the sky is the limit!

Schedule an appointment here to learn more about how you can succeed with 3D printing.

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.