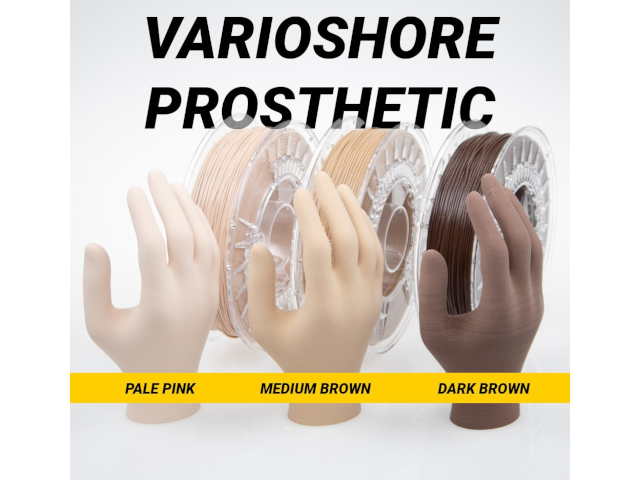

ColorFabb ColorFabb varioShore Prosthetic TPU Filament - 1.75mm (3 pack)

This revolutionary expandable TPU filament from ColorFabb allows you to vary the density and softness of 3D-printed parts by adjusting print temperature and material flow rate. VarioShore TPU Prosthetic uses active foaming technology to produce lightweight, soft-to-the-touch parts ideal for custom prosthetics, orthotics, and human-contact applications.

- The lightweight material density is reduced to 0.5–0.6 g/cm³ when foamed.

- It provides a soft-to-the-touch and comfortable finish, ideal for everyday applications.

- The variable shore hardness allows you to adjust the softness by changing the temperature and flow rate.

- Silver inclusion enhances the antimicrobial properties, making it suitable for prosthetic and orthotic applications.

- The 92A base thermoplastic polyurethane (TPU) is compatible with most standard Bowden and direct drive extruder setups.

- This 3-pack includes three skin tones: Pale Pink, Medium Brown, and Dark Brown.

| List Price: | $231.00 |

|---|---|

| Price: | $189.00 |

| Price: | $... |

| Order Now: | Ships calculating... Free U.S. Shipping |

Unique Properties for Printing Prosthetics and Orthotics

This version of VarioShore TPU is specially formulated for printing prosthetic and orthotic parts. ColorFabb has included silver in the formulation, well known for its beneficial antimicrobial properties in medical and human-contact applications.

- Silver inclusion for enhanced hygiene in prosthetic and orthotic use

- Three realistic skin tone colors for natural-looking prosthetic parts

- Lower temperatures yield more intense, vibrant skin tone colors

- Higher temperatures yield softer parts with a lighter, powder-like skin tone finish

Variable Shore Hardness for Custom Density Control

VarioShore TPU Prosthetic offers variable shore hardness, enabling you to fine-tune the density, weight, and feel of every 3D print. By adjusting the flow rate to 60–70% at higher temperatures, you achieve maximum softness and minimum weight, making it perfect for comfortable, wearable prosthetic and orthotic devices.

- Lightweight with fully adjustable density.

- Active foaming provides a soft touch for daily use.

- Printing at temperatures between 200 and 250 °C expands the material, reducing its density.

| Print Temperature | Foaming | Density | Part Feel |

| 190–200°C | Inactive | Standard | Firmer, more rigid |

| 200–250°C | Active (1.4–1.6× expansion) | 0.7–0.9 g/cm³ | Soft, lightweight |

Flexible Material, Flexible Applications

While purpose-built for prosthetics and orthotics, ColorFabb VarioShore TPU is versatile enough for a wide range of flexible 3D printing applications, including:

- Custom shoe insoles and footwear components

- Soft sporting goods, such as bicycle handlebar grips

- Protective padding and ergonomic accessories

- Any application requiring lightweight, soft-touch, flexible parts

The base TPU is 92A shore hardness, ensuring compatibility with most standard extruder setups for both Bowden and direct drive systems.

By adjusting material flow rates, ColorFabb varioShore enables users to significantly reduce the weight and density of printed parts.

HOW TO SUCCEED WHEN PRINTING WITH VARIOSHORE TPU

The following settings are recommended for successfully printing with this material:

Print Temperature:

- 190°-250°C

Print Speed:

- 20-30mm/s

Print Bed Temperature:

- 20°-40°C

Cooling Fan:

- Users are advised to use the least amount of cooling possible when maximum foaming is desired. For better overhang performance, use 50-100% speed when cooling. Additionally, it is advised to make sure the distance between the nozzle and print surface is not too small, especially if the material is foaming while printing - pressure will need to be released from the hot end to prevent clogging and material feeding issues.

TECHNICAL SPECIFICATIONS

| Diameter Tolerance | ± 0.1 mm |

| Density | 1,2-1,3 g/cm3 |

| Glass Transition Temperature | -20°C |

| Advised on 3D printing temperature | 190°C-250°C |

| Advised 3d print speed | 20-30 mm/s |

| Advised Heated bed | 20-40°C |

| Cooling fan |

|