Protopasta Protopasta Galactic Duel Thermochromic HTPLA Filament - 1.75mm (0.5kg)

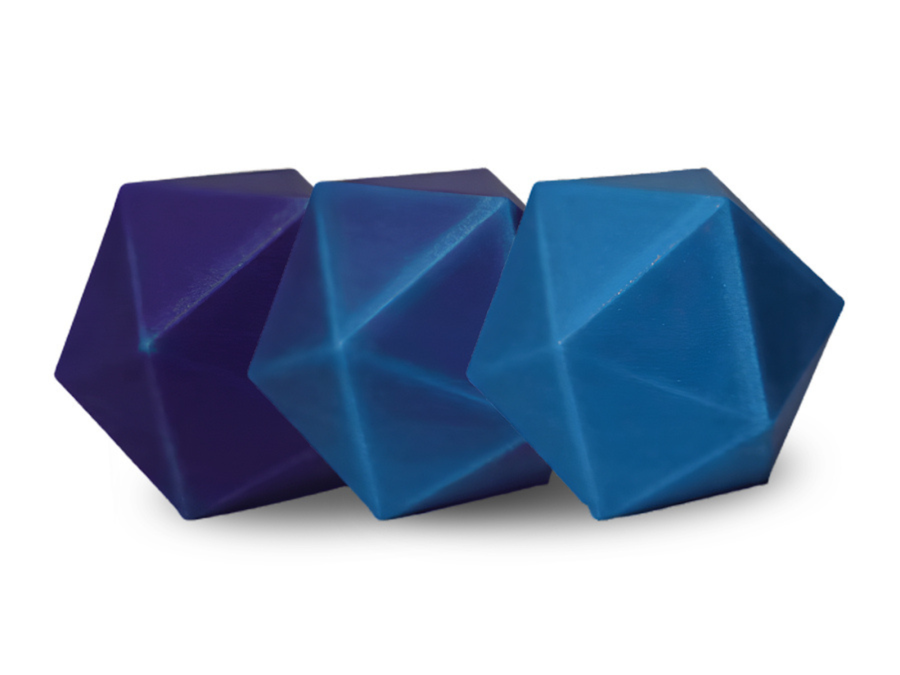

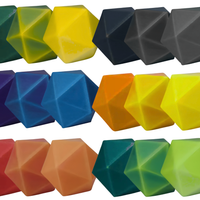

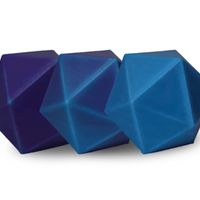

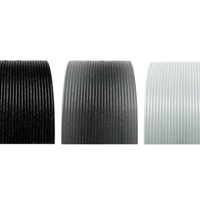

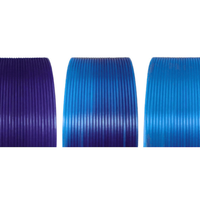

The incredibly innovative and exclusively available Protopasta Thermachromic HTPLA Filament is where science meets creativity. This unique filament changes color with temperature, making your 3D prints dynamic and interactive. Watch as your creations shift color around 31°C (88°F), revealing a captivating finish tailored to your filament choice.

- Thermochromic technology adds a new dimension to your 3D projects.

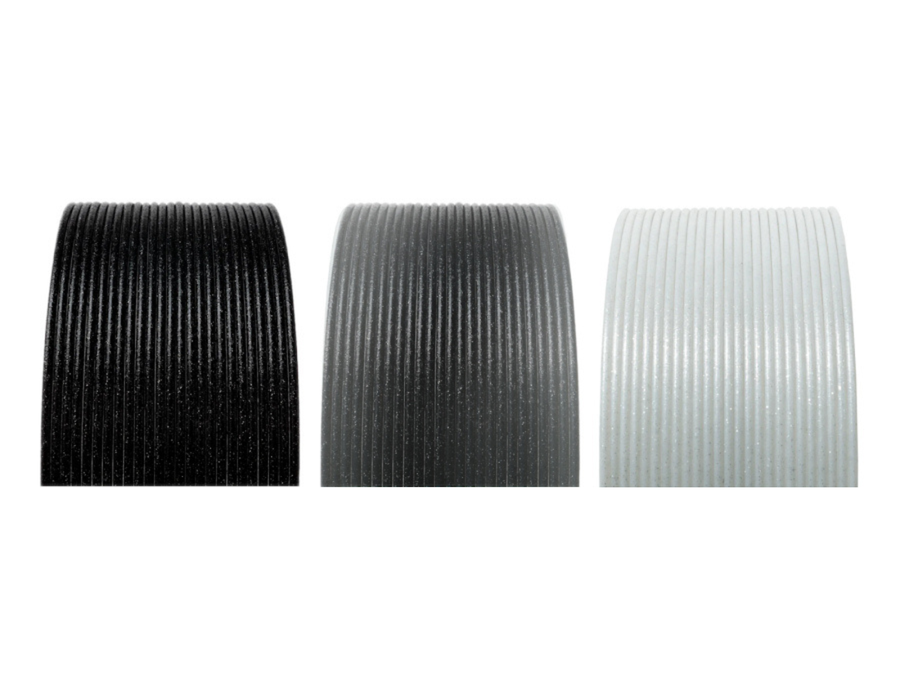

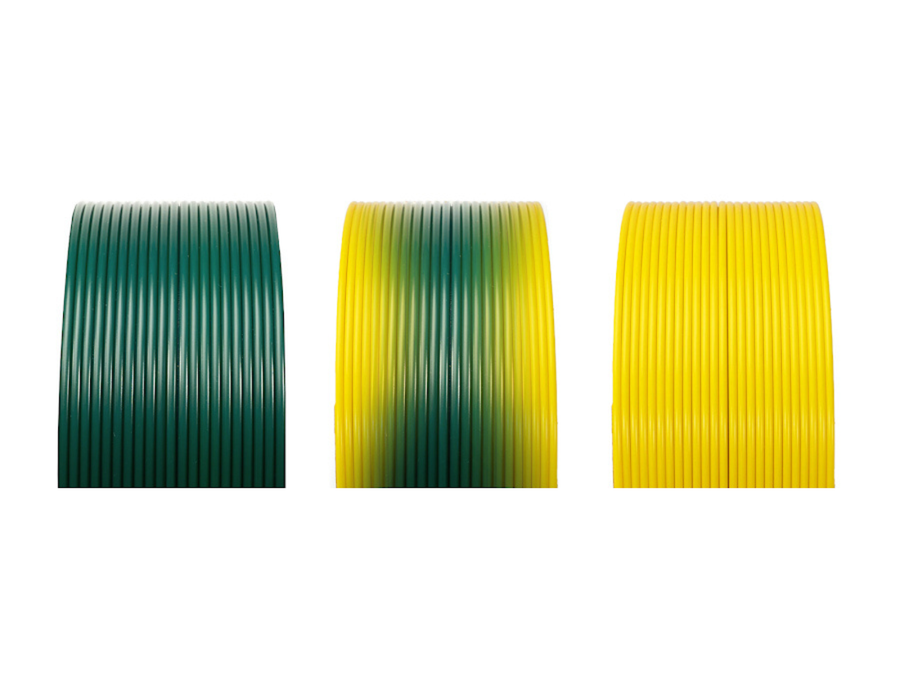

- Premium finishes such as pearl or glitter.

- Proudly manufactured in the USA, these 3D print filaments are a Protopasta exclusive, ensuring top-tier quality and performance.

- Prints easily like PLA

- No hardened nozzle needed

- Easy Heat Treat Process

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Protopasta Thermochromic HTPLA Filament

Captivating Color-Changing Creativity

Unleash the full potential of your 3D printer with Protopasta Thermachromic HTPLA Filament. This filament adds a dynamic touch to your projects by changing color with temperature, offering both visual intrigue and enhanced functionality.

Key Features of the Protopasta Thermochromic HTPLA Filament:

- Experience the magic as your 3D prints change color around 31°C (88°F), adding an engaging and interactive element to your designs.

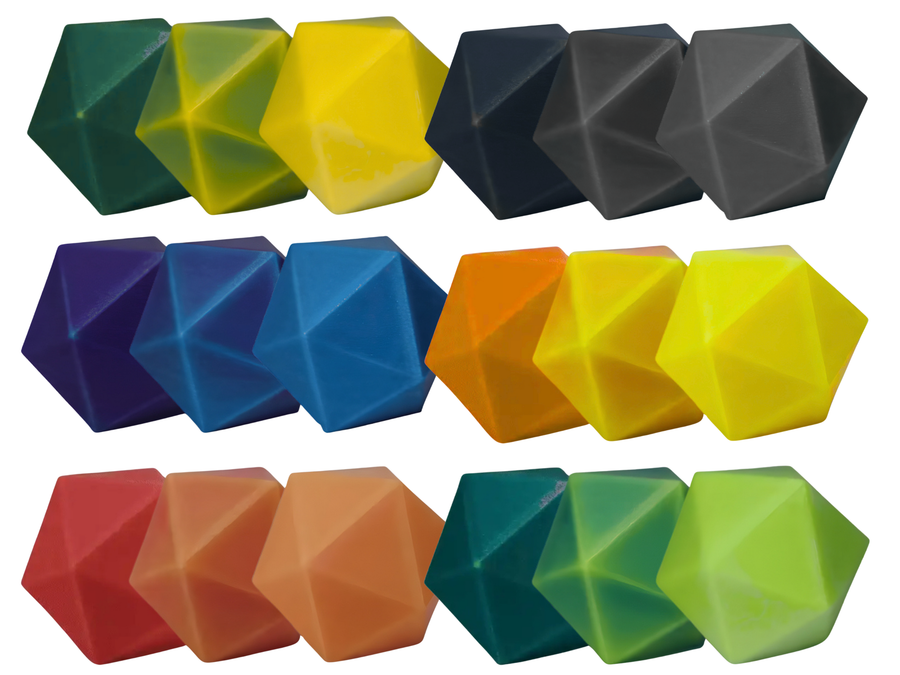

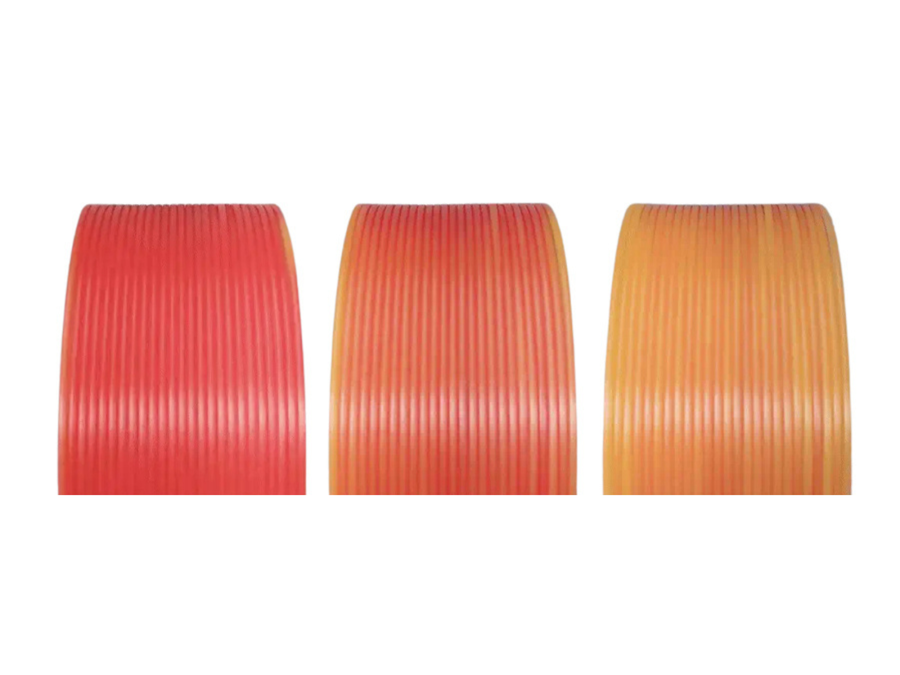

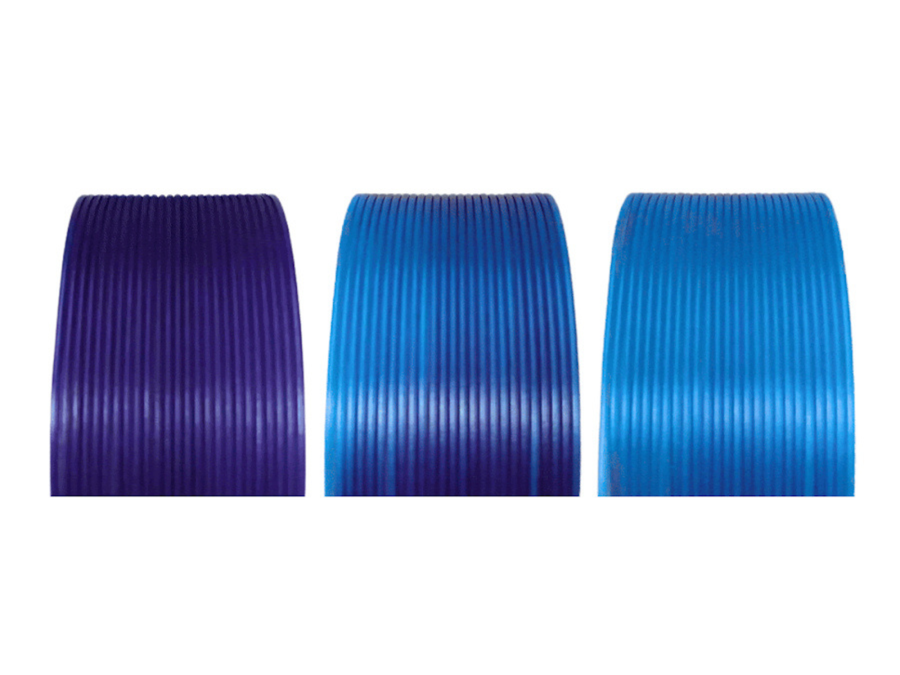

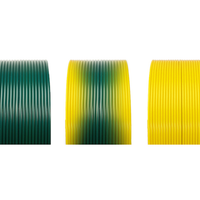

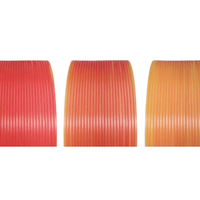

- Enjoy a sophisticated pearl finish in stunning shades like Just Peachy and Chlorophylled, or opt for a glitter finish with Galactic Duel to complement your creative vision.

- Benefit from heat-treating capabilities that provide increased durability and performance at higher temperatures.

- Proudly manufactured in the USA, this exclusive filament guarantees superior quality and reliability.

- Designed for use with most PLA-compatible 3D printers.

Color Transformation at Your Fingertips

Witness your 3D prints transition from one vibrant color to another with temperature changes. With the ability to shift hues around 31°C (88°F), your 3D prints will captivate like never before.

- Add an interactive element to your 3D designs with the heat from your hands alone.

- Diverse finish options from smooth pearl finishes like Sour Apple and Autumn Orange, or opt for the glittery allure of Galactic Duel, each offering a unique aesthetic appeal.

- Enhanced durability from heat-treating capabilities that increase temperature resistance, transforming the filament structure for prolonged functionality.

Strength and Stability

Protopasta's HTPLA is an advanced form of PLA designed to withstand higher temperatures through a process called heat treating (or annealing). Unlike standard PLA, HTPLA can be transformed from an amorphous structure to a crystalline one, enhancing its thermal resistance and durability.

- Heat treating significantly boosts the temperature resistance of your 3D prints, ensuring they maintain their integrity in higher-temperature environments.

- By baking your 3D printed parts post-production, you convert the filament's structure from amorphous to crystalline, locking in durability and performance.

- Annealing enhances machinability and formability, increases ductility and toughness, and provides stress relief to your 3D-printed parts.

Ideal for Advanced Applications

- Heat treating HTPLA changes its internal structure, allowing it to maintain its properties well above the glass transition temperature (Tg) and up towards the melting point (Tm).

- The shift from an amorphous to a crystalline structure means that HTPLA retains its strength and functionality even in higher temperature environments, making it ideal for more demanding applications.

- This transformation significantly broadens the useful temperature range of HTPLA, as demonstrated by the difference between Tg and Tm in differential scanning calorimetry (DSC) results.

- With its enhanced properties, HTPLA is perfect for 3D projects requiring higher thermal stability without sacrificing the ease of use associated with standard PLA.

How to Anneal HTPLA

To fully capitalize on the benefits of HTPLA, heat treating (or annealing) is essential post-printing, as the crystalline structure reverts to amorphous when melted. Follow these improved step-by-step instructions to enhance your 3D prints:

Gather Your Materials:

- A large oven with precise temperature control and stability.

- Aluminum foil, if you have a small oven or one with glowing coils, to shield the 3D prints from direct heat.

- A flat surface, such as a wood block, cutting board, or silicone mat, is placed on a baking sheet.

- Your HTPLA 3D printed parts, with supports if necessary.

Prep Your Oven:

- Preheat the oven to a temperature range of 95-120°C (200-250°F).

- If using an electric oven, wait until the coils are no longer glowing. If glowing coils are unavoidable, cover them with the foil sheet to prevent direct heat exposure before preheating your oven.

Bake Your 3D Prints:

- Once the oven is preheated, carefully place your 3D printed part on the prepared surface and insert it into the oven.

- Bake the part for approximately 10 minutes. Or until you observe a change in the material's appearance, indicating the transformation to a crystalline structure.

Technical Specifications

Material Properties

| Properties | Value/Description |

| Base Material | Heat treatable PLA w/ high temp resistance |

| Characteristics | Low odor, non-toxic, renewably sourced |

| Molecular Structure |

Amorphous or partially crystalline

|

| Max particle size | 0.1 mm (may limit resolution) |

| Density | Approximately 1.24 g/cc |

| Length | Approximately 346 m/kg (1.75 mm) & 130 m/kg (2.85 mm) |

| Min Bend Diameter | 15 mm (1.75 mm) & 40 mm (2.85 mm) |

| Glass Transition (Tg) Onset |

Approximately 60°C (140°F) |

| Melt Point (Tm) Onset | Approximately 155°C (310°F) |

| Max Use |

|

Print Settings

| Nozzle Temperature [°C] | 206 |

| Heated Bed Temperature [°C] | 60 |

| Print Speed [mm/s] | 25-45 |

| Flow Rate/Extrusion Multiplier [%] | 100 |

| Extrusion Width [mm] | .45 (.05mm larger than nozzle size) |

| Volume Flow Rate [mm³/s] | 2-3 |

Heat Treating

| Part Axis | Percentage |

| Scale Values (x/y-axis) | 102.2% |

| Scale Values (z-axis) | 99% |

| Typical Heat Treat Temperature | Typical Heat Treat Time |

| 95-110°C | Approximately 10 minutes |

Tips & Tricks

- HTPLA doesn't require drying, but if drying, do not dry above the glass transition temperature, as this can heat treat HTPLA. For PLA, dry at 50°C (125°F).

- Use a 0.4 mm brass or plated brass nozzle with a heater block sock at a temperature of 195 - 225 °C and a bed temperature of 50 - 56°C.

- Ensure your 3D print bed is clean with adhesive.

What's In the Bag?

All Protopasta 3D Printer Filament is wrapped in plastic and packaged in a vacuum-sealed bag with a desiccant pouch.