Choosing the Right 3D Printing Support Material // Comparison Guide

Our MatterHackers Pros take the time to compare various support materials so you have all the knowledge you need to get started with them.

3D printing is an amazing technology that allows you to bring the wildest designs you can create from the digital world into reality. Some 3D models that you create will be simple enough and need minimal to no support material - that is the scaffolding that builds up and around your 3D prints to make sure structures aren’t attempted to be made in mid-air. Most of the time you can get away with using your build material as your support material, but there will be times where it’s not possible to have the supports there while printing and still be able to remove them once finished. That’s where specialized 3D printing support materials come in.

Let's jump into it -

PVA (Polyvinyl Acetate)

PVA is often used as an adhesive to promote bed adhesion for certain materials, and it’s also quite handy as a support material. In general, materials that work well with PVA glue stick as the bed adhesive of choice will benefit from using PVA as its support material. As you may have discovered, PVA glue stick is water soluble and PVA filament is no different; simply soak the supported 3D print in a tub of warm water and change it when the water becomes saturated. To accelerate the process you can chip away at the supports just the same as regular supports or even have a pump in the tub to circulate the water and more thoroughly clean the print. Unlike traditional supports you are able to generate them as aggressively as necessary without fear that they will permanently bond to the 3D print; drop the Support Z-distance to 0, set support to everywhere, and rest easy knowing that even internal cavities can be properly supported before the support is washed away. This list is not exhaustive, but PVA should be your support material of choice for PLA and its derivatives like Tough PLA, for Nylon, PETG, TPU, and PVB. Be sure to adequately dry out your spool before printing for best results, as PVA tends to be hygroscopic and will absorb water from the air, which hinders its ability to print cleanly and without stringing or it can even clog your hotend.

Breakaway

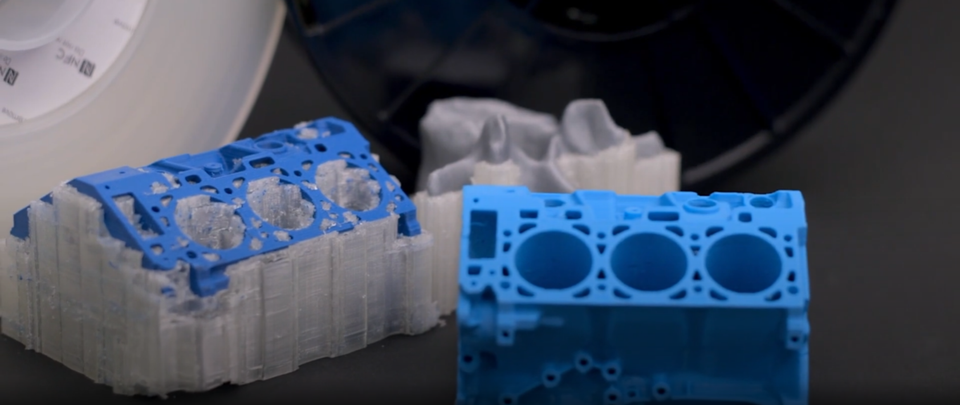

There are scenarios when you just don’t have the time to wait for support to dissolve but you still need your surfaces to be crisp and clean: breakaway support materials are the way to go. When the build and support materials are the same, it means you will need to adjust the distance between the top of the support to the bottom of the finished 3D print - too close and it becomes part of the print, too far and the bottom surface is a droopy, rough mess. With breakaway support materials, you can decrease that distance without worrying about permanently bonding the two together while still maintaining a good surface finish. This support material and method is best reserved for 3D designs that are tough and without delicate intricacies, as you will be using pliers, knives, and scrapers to cut through the supports. Breakaway performs best when paired with PLA, PETG, or ABS.

HIPS (High Impact Polystyrene)

As versatile as PVA support materials are, they still have a temperature limit and general material properties that impact their performance. Materials like ABS and ASA print at temperatures much too hot for PVA and should instead be paired with HIPS (High Impact PolyStyrene). HIPS has a printing temperature more closely in line with ABS and ASA, so it is significantly less prone to warping and deforming from the heat generated by the freshly-laid filament, and also adheres to the filament, preventing it too from warping away from the supports. Just like PVA you can set your Support Z distance to 0 and have your part printed directly onto it for a clean bottom surface. Unlike PVA you won’t be able to dissolve it under some warm water and will need to use limonene - a solvent derived from oranges - in order to have the HIPS turn to a goop and fall away from the 3D print. Limonene is a safe solvent to work with as it is non-toxic, non-corrosive, and biodegradable!

Ionic Hi-Temp Hybrid Support Material

More recently, Ionic Hi-Temp Hybrid Support Material was introduced to bring the utility of PVA to the materials that print at higher temperatures. Rather than involving a solvent that you may not already have, Ionic is completely dissolvable in water just like PVA and in some scenarios behaves as a breakaway support material - virtually falling off of the finished 3D print. While it was formulated with nylon and its fiber-filled derivatives like NylonX, NylonG, and NylonK in mind, it performs exceptionally well with other high temperature materials like ABS, PETG, or RYNO.

Just as it is important to pair the right printing surface to your build materials, it is important to find the right support material to pair with the design at hand. With the help of this comparison you should be on your way to printing all of your 3D designs fully supported and ready for any geometry you can come up with. To learn more and to order your spool of support today, check out the collection here.

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.