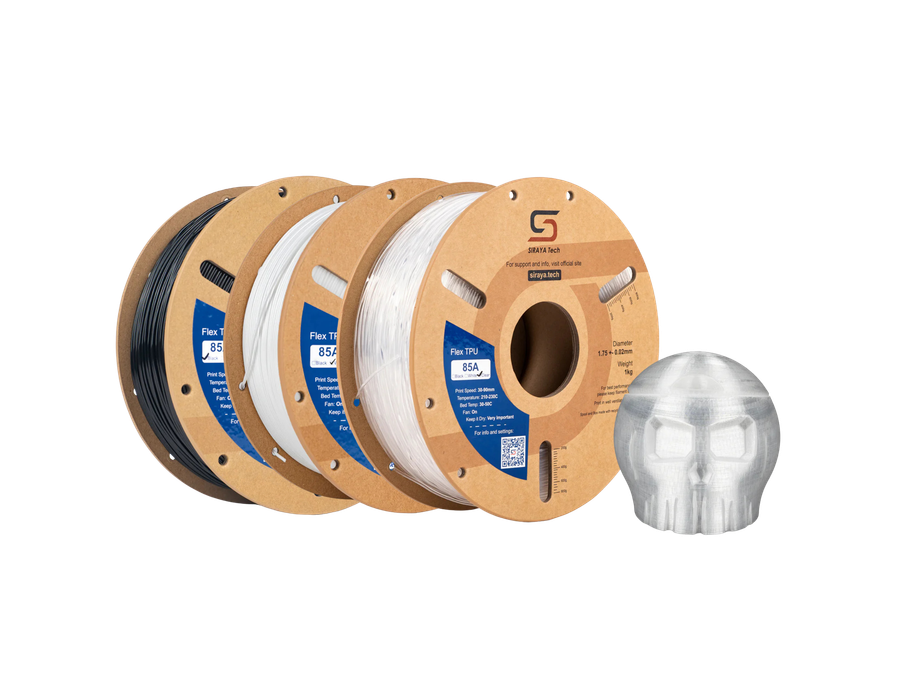

Siraya Tech Siraya Tech Flex TPU 85A Filament - 1.75mm (1kg) 1kg

Siraya Tech Flex TPU 85A is a high-flow, flexible filament designed for fast, reliable TPU printing. With softer Shore 85A hardness, excellent toughness, and improved extrusion performance, it’s ideal for wearables, flexible parts, and durable functional prints. Certified for skin contact, it delivers comfort without sacrificing strength.

- Softer & More Flexible: Shore 85A hardness provides a smooth, ideal for wearables and bendable parts

- High-Speed TPU Printing: Prints up to 5× faster than standard TPU with improved flow and extrusion stability

- Tough & Durable: Excellent impact resistance and strength for functional, load-bearing flexible components

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Siraya Tech Flex TPU 85A

Resilient and Flexible

Designed for hobbyists and professionals alike, leverage the unique properties of Flex TPU 85A for flexible and resilient printing projects. With a Shore hardness of 85A, this filament offers a superior softness for projects requiring exceptional pliability, like wearables, protective gear, and flexible guards. Siraya Tech filament is made for ease of printing, while guaranteeing exceptional print quality.

Key Features of the Siraya Tech Flex TPU 85A Filament:

- Enhanced flexibility for wearables, prototyping, medical accessories, and everyday items

- Excellent impact resistance with high durability and toughness

- Ease of printing with easy extrusion and increased bed adhesion, ensuring smoother printing experiences

- High-speed printing performance at up to 5x faster

Superior Flex & Toughness

TPU 85A delivers excellent flexibility and elasticity, making it ideal for durable, bendable prints. It offers the perfect balance of pliability and strength, allowing parts to flex while remaining tough enough for load-bearing applications.

- Flexible for bendable, impact-resistant prints

- Tough and strong for lifting and functional parts

- Soft, comfortable feel for wearable applications

Recommended Print Settings

| Recommended Settings | |

| Nozzle Temperature | 200 - 225 °C |

| Recommended Nozzle Diameter | > 0.2 mm, best results with 0.4 mm |

| Recommended Build Surface | PEI or Glass with glue |

| Build Plate Temperature | 20 - 50 °C |

| Cooling Fan Speed | On |

| Print Speed | 30 - 90 mm/s |

| Retraction Distance | 1 - 3 mm |

| Retraction Speed | 1800 - 3600 mm/min |

Mechanical Properties

| Mechanical Properties | |

| Tensile Stress at Break | 24± 3.0 MPa |

| Tensile Stress at 100% | 6.7 MPa |

| Tensile Stress at 200% | 8.4 MPa |

| Tensile Stress at 300% | 10.8 MPa |

| Elongation at Break | 580% |

| Hardness | 85A |

Printing Tips

- Storage: Store in the provided moisture-resistant aluminum bags when not in use. For prolonged storage, using a dry box with desiccant, maintaining humidity below 15% is ideal.

- Drying: If moisture absorption is suspected, dry the filament at 50 - 60°C for 4 - 6 hours in a filament dryer. Find filament dryers here.

- Printing: Ensure a clean, level print bed. Printing with a bed temperature of 20 - 50°C is recommended, adjusting to your printer's settings. For ideal extrusion temperatures, use a range of 200 - 225°C.

- Note: The black variant performs better at slightly cooler extrusion temperatures compared to the white variant.

- Troubleshooting:

- Stringing: Try adjusting retraction settings and lowering print speeds. Additionally, ensure the filament's moisture level is within acceptable limits.

- Poor Bed Adhesion: Consider using a glue stick or slightly increasing the bed temperature to improve adhesion.