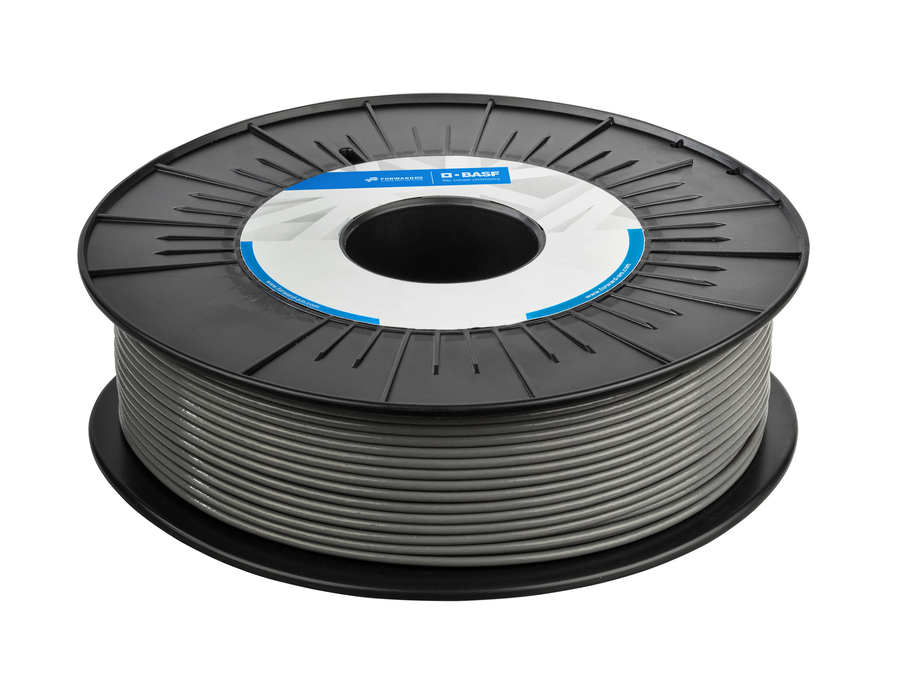

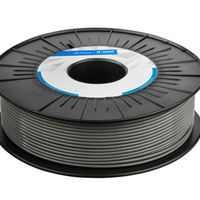

Forward AM Forward AM Ultrafuse 316L Metal 3D Printing Filament - 2.85mm (3kg)

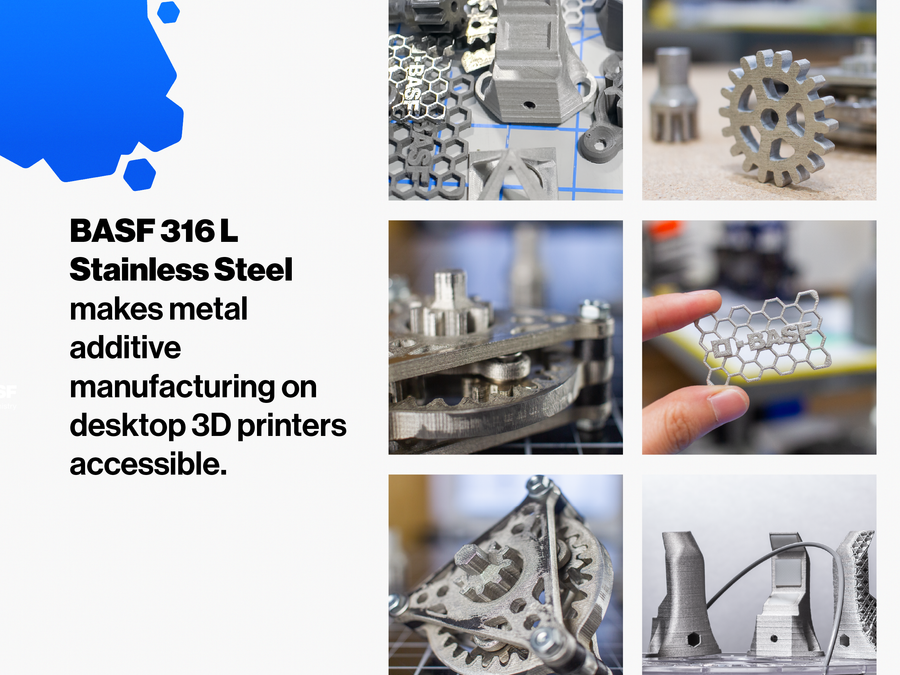

BASF 3D Printing Solutions' Ultrafuse 316L Metal 3D Printing Filament makes metal additive manufacturing on desktop 3D printers accessible.

Top Ultrafuse 316L Features:

• Easily ship out for debinding and sintering Ultrafuse green parts

• Produce end-use products made from stainless steel

• Make functional prototypes from real metal

• Cost-effective and convenient to print and process

• Elevate the 3D printing experience to an industrial level

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

BASF Ultrafuse 316L Metal Filament

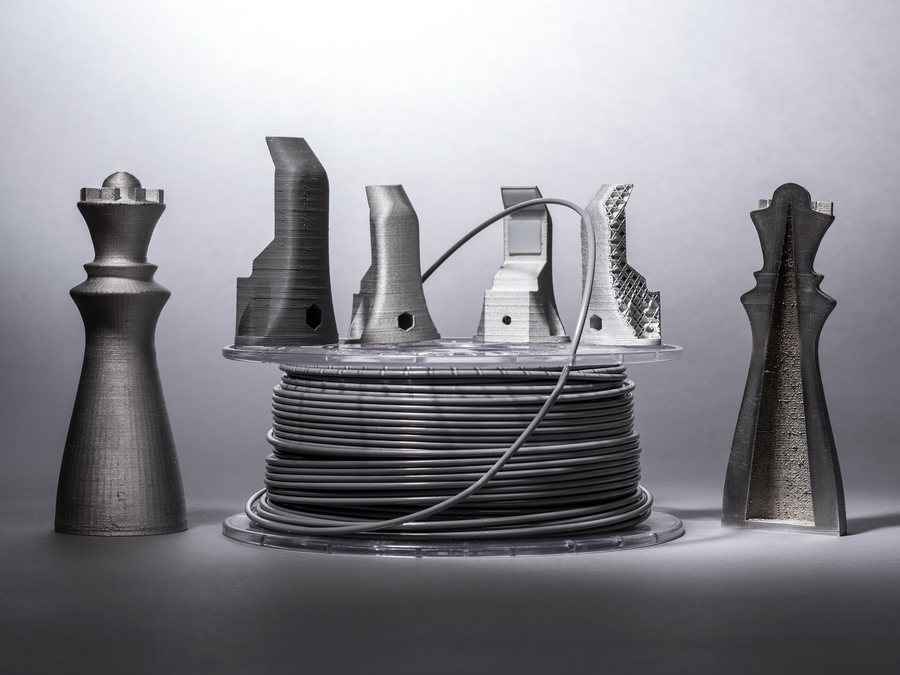

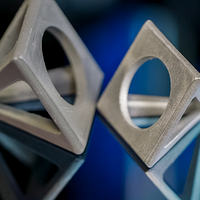

3D Print Steel Parts

BASF Ultrafuse 316L is a convenient, affordable way to create stainless steel metal parts on your desktop 3D printer.

Here are the key features of BASF Ultrafuse 316L:

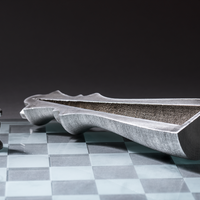

- Produce end-use products made from stainless steel

- Make functional prototypes from real metal

- Cost-effective and convenient to print and process

- Elevating their 3D printing experience to an industrial level

- Easily ship out for debinding and sintering Ultrafuse green parts

- Print on nearly any desktop 3D printer

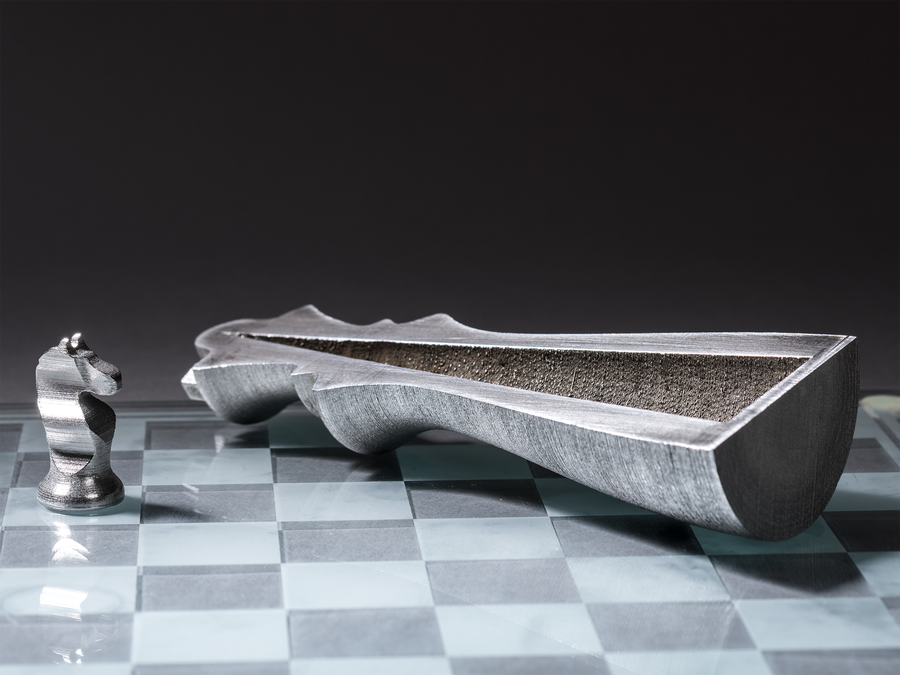

3D Print Stainless Steel Parts

Formerly the provenance of thermoplastics, Ultrafuse 316L allows production of genuine metal parts from your desktop 3D printer, saving huge costs in Metal Injection Molding or metal machining.

- Made from 80% 316L stainless steel particles in polymer base

- Specifically engineered for desktop 3D printing

- Non-magnetizable with high corrosion resistance

- Applications include:

- Functional Prototyping

- Medical Equipment

- Automotive Parts

- Chemicals pipes, pumps and valves

- Mold inlays with near-surface cooling

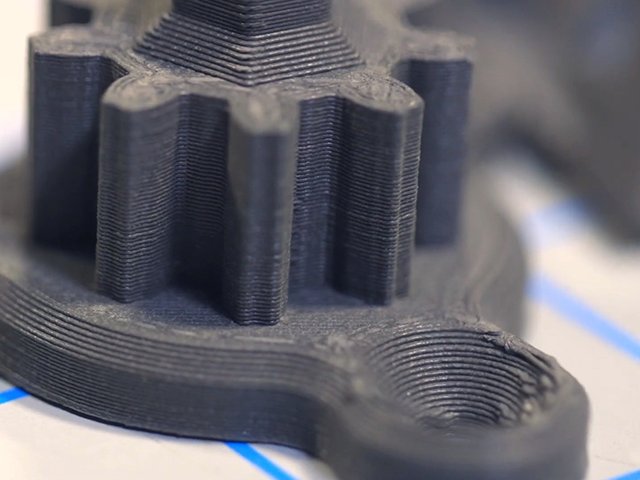

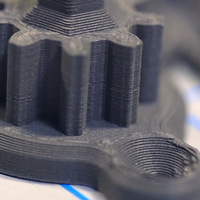

Print On Any Desktop 3D Printer

The path to printing metal is shorter than you might think, with virtually any desktop 3D printer being capable.

- Install a hardened nozzle

- Make sure your bed is heated

- Prints on an Ender, an Ultimaker, a Modix, or a Voron!

- Read best to print metal filament in our article, here.

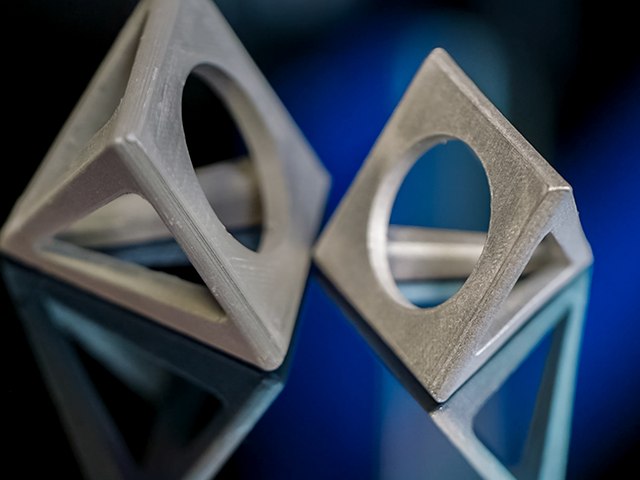

Quick and Easy Debind and Sinter Process

Purchase a Processing Ticket, to easily get your part through the necessary debinidng and sintering process that turns your printed, "green part" into a fully metal, "brown part".

- Mail your parts to the experts at DSH within three months of purchase

- We work with DSH to quickly process parts on scheduled runs

- DSH mails your processed, solid steel parts back to you!

- Purchase additional Processing Tickets at your convenience

- How to Prepare 3D Printed BASF Ultrafuse 316L Parts for Processing

PROCESSING SCHEDULE

DSH has Debinding and Sintering runs scheduled on the first Tuesday of every month, and parts need to have arrived to DSH on the Friday before. What counts as properly packaged and shipped parts? Check out our "How to Prepare Ultrafuse 316L Parts for Debinding and Sintering" guide.

TECHNICAL SPECIFICATIONS

- Requires one BASF Ultrafuse 316L Processing Ticket

- Within 48 business hours of purchase, please expect a follow-up email from a MatterHackers' support team member with your unique processing ticket code, packaging instructions, and form.

- This processing ticket comes with Standard Return Delivery. Parts will return to the customer between 2 - 5 business days AFTER green parts have been debound and sintered. Time of delivery will be based on the sender address' location in proximity to DSH's facility.

- This processing ticket only covers return delivery within the U.S. Additional shipping charges may be applied to customers outside of the U.S. If you want to use a processing ticket and live outside of the U.S., please contact support@matterhackers.com for options.

- Processing tickets expire three months from the date of purchase.

- Recommended Extrusion Temperatures: 230 - 250 °C

- Recommended Bed Temperature: 100 - 120°C

- Recommended Print Surface: Glass Bed with Dimafix Bed Adhesive

- Recommended Nozzle: Any Abrasion Resistant Nozzle

- Make sure your nozzle is 100% purged of other filaments before printing

- Density: 7800kg/m³

- Filament Diameter: 1.75mm / 2.85mm

- Spool Size: 3kg

- Print Speed: 15 - 40mm/s

- Part Cooling: None

Click here to view or download the Ultrafuse 316L TDS.

CONSIDERATIONS FOR SUCCESS

- Learn the Do's and Don'ts to Designing Your Metal Prints for Debinding and Sintering Success Here.

- Process Your Printed Ultrafuse 316L Parts Here.

- Learn How to Properly Prepare Your Prints for Debinding and Sintering Here.

FREQUENTLY ASKED QUESTIONS

- Q: What is the shrinkage % with this material?

- A: It is recommended to scale the part up by 120% (119.82% for more accuracy) in the X and Y, then scale the Z up by 126% (126.10% for more accuracy) for printing.

- Q: Can the debinding and sintering be done without outsourcing? Can I purchase the equipment and debind and sinter the parts myself?

- A: It is absolutely possible to process the Debinding and Sintering steps yourself, if you have access to a facility with the correct equipment or are interested in doing debinding and sintering on the scale that justifies the capital equipment. The most cost-effective method for the majority of users will be utilizing the network of debinding and sintering service centers prepared to handle the parts. To shorten research and negotiation time, you can purchase a MatterHackers BASF Ultrafuse 316L Processing Ticket that connects you with a reliable debinding and sintering company at a simple, established price.

- Q: How much does outsourcing debinding and sintering cost?

- A: Outsourcing cost ranges widely depending on the debinding and sintering company, bulk of parts being processed and method used. For a set cost on processing up to 1 kg of BASF Ultrafuse 316L printed green parts, check out our BASF Ultrafuse 316L Processing Ticket. Please note that every purchase of a BASF Ultrafuse 316L Metal 3D Printing Filament spool from MatterHackers comes with 1 free BASF Ultrafuse 316L Processing Ticket.

- Q: Can I use support materials for this filament?

- A: We do not recommend using supports with your Ultrafuse 316L prints. While it is possible to use breakaway and water soluble supports to help produce your Ultrafuse 316L parts, they will not be able to maintain the print's shape during the sintering process, which will lead to deformity. Using Ultrafuse 316L filament as its own support material is also possible, but it will require machining, cutting, or grinding the support off after sintering.