How to Prepare Ultrafuse Metal Parts for Debinding and Sintering

Learn how to properly prepare, package and deliver your 3D printed BASF Ultrafuse 316L and 17-4 PH green parts for debinding and sintering.

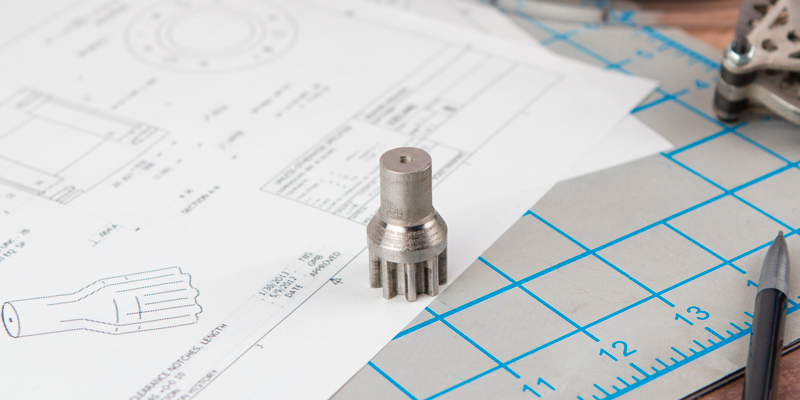

Metal 3D printing has not only increased in popularity over the years; it's also become more attainable for the common consumer as new game-changing products enter the market. Materials like BASF's Ultrafuse Metal Filament make metal additive manufacturing through desktop 3D printers an accessible reality. Starting right from the home, any advanced user or professional can produce metal parts on a Fused Filament Fabrication (FFF) 3D printer that comprises of the necessary components to extrude abrasive materials at high temperatures. BCN3D Sigmax R19, Ultimaker S5, and Pulse are just a few of many 3D printers capable of this, right out of the box.

While metal digital fabrication can start from the home, there are a few proceeding steps that may require external services. After a part has been 3D printed with metal filament, it is referred to as a "green part" in this state until it enters the next two fundamental steps—debinding and sintering. Debinding is the process of removing plastic material from green parts to produce what is called a brown part. Sintering is the process of turning the leftover powdered metal in the brown part into solid metal through heat. For a deep dive into the entire 3D metal printing process and why these two steps are crucial to producing metal parts, check out our article "How to Succeed with 3D Printing Metal on a Desktop 3D Printer."

Debinding and sintering are not common practices as they require a great deal of money for industrial level machines. Because it is extremely pricey for someone to jump into debinding and sintering, we have found that it would be more affordable to outsource these tasks to a company that specializes in these steps. Where can you find a reliable debinding and sintering company? How do you prepare your parts for these processes? What can you do to make sure this outsourcing goes smoothly? Read our detailed guide below for step-by-step instructions on how to successfully prepare your green parts for outsourcing debinding and sintering services.

Preparing Prints for Processing

Step 1 - Follow Printing Parameters for Printing Green Parts

- It is crucial that you print your green parts with a clean nozzle. Please either use a new nozzle or take extra steps to purge the nozzle you intend to use of any foreign materials (PLA, ABS, PETG, Nylon, etc.) before printing with BASF Ultrafuse metal filament.

- Confirm that you've printed your green parts based on our suggested design considerations under the "Design for Successful Manufacturing" section here.

- One flat side of the part that sticks to the print bed is necessary to 3D printing success. To maintain strong bed adhesion, we highly recommend using Dimafix bed adhesive on a glass bed.

We strongly recommend following these parameters as they boost your chances of successfully transforming your green parts into solid steel during the debinding and sintering process.

Step 2 - Post Process Printed Green Parts

- Remove any foreign substances that may still be on your printed green part such as oils, fingerprints, bed adhesives (glue, tape, etc.), and other residue.

- Failure to remove foreign materials will lead to an unsuccessful debinding and sintering process. Take extra steps to print with a clean nozzle and clean up ALL foreign materials listed above to reduce the chances of your parts potentially exploding in the furnace and resulting in a failed processing run.

- Clean up any printing artifacts that are leftover (such as rafts, globs, strings, etc.) using either an art knife, a deburr tool, or small file.

- If warping occurred during the printing process, sand the base of your flat part by "lapping" the bottom with sandpaper.

- We've found that Dimafix on a glass bed is great at preventing warping.

Take some time to clean up any blemishes your green parts may have accrued during printing. This goes a long way to ensure your parts succeed during the debinding and sintering process. For more tips on successfully printing and post-processing your metal 3D printed green parts, check out our article here.

Step 3 - Purchase a Processing Ticket

- If you haven't already done so, you can purchase a processing ticket here.

- Within 48 business hours of purchase, please expect a follow up email from a MatterHackers' support team member with your unique processing ticket code, packaging instructions, and form.

- One processing ticket covers up to only 1kg in weight of printed green parts. More than one ticket must be purchased if you would like more than 1 kg of green parts to be debound and sintered in a single run.

- Processing ticket codes only cover return delivery within the U.S. Additional shipping charges may be applied to customers outside of the U.S. If you want to use a processing ticket and live outside of the U.S., please contact support@matterhackers.com for options.

- Choose one of two options for the estimated time of return delivery (after the debinding and sintering process)

- Expedited Shipping - Return delivery will take 1 business day

- Standard Shipping - Return delivery will take between 2 - 5 business days (depending on the return address' proximity to DSH's location)

- Return delivery only covers shipping from DSH, a professional debinding and sintering company, back to your specified return address. Shipping from your location to DSH must be purchased separately.

- Receive an email from MatterHackers with a special code. This code will serve as your processing ticket and must be included in your package, along with the form in Step 4 and your printed parts. Failure to pack your code, form and parts will result in a delay.

- DSH begins processing orders the first Tuesday of every month. This excludes holidays.

- i.e. If your package arrives just before the week that Christmas falls on the fourth Tuesday of December, then your parts will be processed later in the week. Refer to the schedule posted on the Processing Ticket product page for accurate dates.

- To have your package processed on the week of a run, it must arrive no later than the Friday before the scheduled run.

- i.e. If a run is scheduled Tuesday, September 10th, then your package must arrive at DSH's facility by Friday, September 6th, if not earlier.

- If a package arrives the week of a scheduled run, your package will not be processed until the next run.

- i.e. If your package arrives on Monday, September 9th (the day before a scheduled run) or later, your package will not be processed that week. It will be processed on Tuesday, September 24th instead (the next scheduled run in this example).

Instead of spending hours researching reliable debinding and sintering companies and negotiating quotes, this MatterHackers BASF Ultrafuse Metal Processing Ticket expedites that process with a manufacturer and price ready to go at checkout. Buy a ticket. Receive a code. Print out the form in Step 4 with the code to ship with your parts.

Step 4 - Weigh Parts and Fill Out Form

- Weigh all the green parts you plan to ship with your processing ticket. Again, one processing ticket only covers up to a total of 1kg in weight of BASF Ultrafuse printed green parts.

- If the total weight of parts you ship exceeds the weight your processing ticket(s) covers, your processing run will be delayed until you either...

- ...purchase the required number of tickets to cover the weight of parts shipped

- ...or if you acknowledge and agree that your shipment will not be fully processed (i.e. a sender agrees that only 2kg of their 3kg package will be processed because they only purchased two processing tickets).

- If the total weight of parts you ship exceeds the weight your processing ticket(s) covers, your processing run will be delayed until you either...

- Fill out and print the form linked here with the requested information.

- OPTIONAL—you may also choose to print out a photo of all your green parts. While not necessary, we strongly recommend this step for proper tracking of the state of your prints before shipping.

Filling out this form minimizes miscommunication between you and DSH while also maximizing success for this debinding and sintering process.

Step 5 - Properly Package Parts

- Bubble wrap each individual part you plan on shipping for debinding and sintering. Better protection of your parts equals reduced risk in shipping damage.

- Place your printed form and bubble wrapped parts into a sturdy corrugated cardboard box that is large enough to hold all the parts that will be shipped.

- If possible, try to pack the listed items above in a box with just enough room to hold your parts. Using a box much larger than the parts bundled together will leave them susceptible to damage during shipping.

- If there is a lot of wiggle room in the box, either use extra bubble wrap or throw in packing foam to reduce as much movement as possible.

Green parts, while not extremely delicate, are also not impervious to bumpy shipping deliveries like any other package. In order to increase the chances of your green parts arriving intact upon arrival, we strongly recommend taking extra care to package your parts.

Step 6 - Ship Parts and Form

- Confirm your sturdy cardboard box includes your printed email, form, and parts.

- Pay for the postage and ship to the following delivery address—including your Processing Ticket Code as an "Attention":

DSH Technologies, LLC

ATTN: [enter processing ticket code here]

107 Commerce Road

Cedar Grove, NJ 07009 USA

- With a permanent marker, legibly write the processing ticket code on the outside of the package where it is clearly visible.

- This helps quicken the check-in process.

That's it! Preparing and shipping your green parts for processing is complete on your end. If your parts arrive at DSH no later than the Friday before the scheduled run, then your parts will be processed the Tuesday they are performing a run, debound and sintered on Wednesday, and shipped out no later than Thursday afternoon. Depending on what return shipping service you chose at checkout for your processing ticket, your parts may arrive the next day on the Friday or return anywhere between 2 - 5 business days depending on where your return address is located in proximity to DSH.

Once your now metal Ultrafuse parts have returned, you can perform some post-processing on them for a final touch-up (which you can learn more about here) and finally put them to use.

If you have any questions regarding processing ticket and this process, feel free to contact one of our friendly staff members at support@matterhackers.com or call us at +1 (949) 613-5838.

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.