- Home

- Store

- 3D Printer Filament

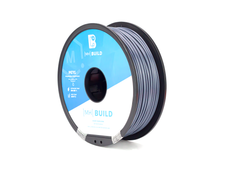

- PETG Filament

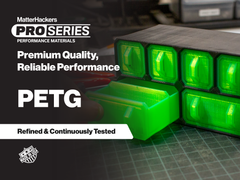

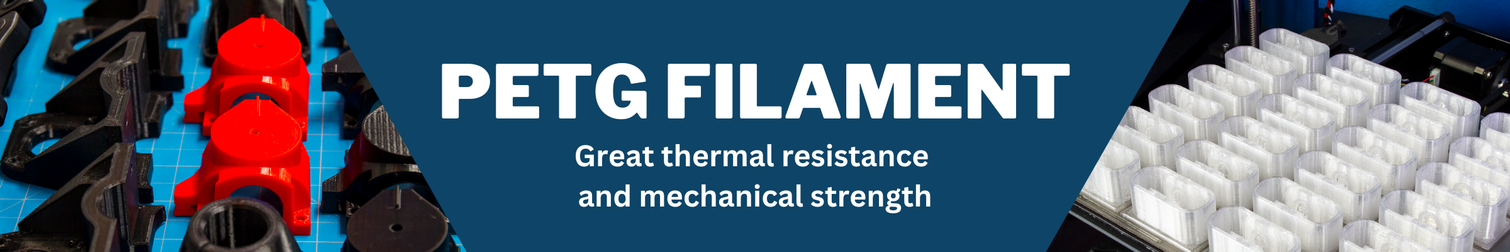

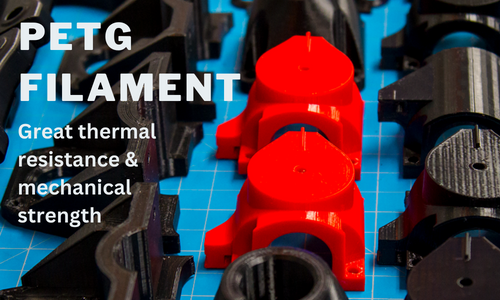

PETG 3D Printing Filament

PETG (Polyethylene Terephthalate Glycol) is a material you likely touch everyday without realizing it. Used is mass quantities as water bottles and coffee shop takeout cups, PETG is one of the most widely-used thermoplastics on the planet thanks to it's natural clarity and easy of recycling and reuse. As a 3D Printing filament, PETG has good thermal resistance and mechanical strength on top of being the go-to material for any translucent colors since natural PETG is almost entirely clear. If you are looking at PETG for the first time, check out our guide on How To Succeed When Printing With PETG.

PETG Filament Collections

All PETG Filament 3D Printer Filament

About PETG Filament

What is PETG filament?

Commonly known as PETG, polyethylene terephthalate glycol is a thermoplastic polyester that provides significant chemical resistance, durability, and excellent formability for digital manufacturing. For tips and tricks on 3D printing PETG, check out How To Succeed When Printing With PETG.

What are the properties of PETG filament?

PETG has multiple advantages in 3D printing and digital fabrication:

- Extremely easy to print

- No odor and little to no warping during printing

- 100% reclaimable material

- Cost-effective when compared to either acrylic or polycarbonate

- Good chemical and thermal stability after printing

- Transparent in its raw form

- Has a high-temperature tolerance post-printing

What are the best settings for 3D printing PETG?

PETG requires slightly higher temperatures than PLA for printing. It is also highly recommended that a heated bed be used.

- 250°C +/- 10°C is the optimal printing temperature for most machines

- A heated build plate at 65°C is nominal for improved adhesion

- PEI is the best surface for PETG; blue painter’s tape also works well for adhesion

- Layer adhesion works best with low to no layer cooling fans (50% max speed on larger overhangs)

What is the best build surface for printing PETG?

- LayerLock Powder-Coated PEI or LayerLock Garolite - Both surfaces are ideal for PETG printing and have good success for first-layer adhesion.

What are some things to look out for when 3D printing with PETG?

Stringing: This typically occurs when the temperature is too high, or the retraction settings are too low.

Low Layer Adhesion/Layer Splitting: This typically occurs when the temperature is too low, so the layers are not bonding during printing. Increase temperature by 5°C and try again until you obtain optimal interlayer adhesion.

Does PETG need to be dried before printing with it?

PETG is hygroscopic, which means it will absorb moisture from the atmosphere. Best practices before 3D printing with any PETG filament is to thoroughly dry it out with a PrintDry PRO for several hours (or overnight if you have the time) and print with it immediately.