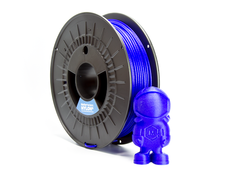

NylonG is glass-fiber infused 3D printing filament that has excellent impact-resistant capabilities. NylonG also has excellent inter-layer adhesion and incredible tensile strength. Under stress, NylonG parts have very little flex, and they retain their dimensional accuracy better than nylon alone. NylonG filament is excellent for creating parts that need to stand up to a beating or need to absorb large amounts of kinetic energy. Under repeated shock, glass-fiber reinforced NylonG 3D prints maintain their shape and structural integrity.

Taking advantage of the benefits of both nylon and the glass-fiber reinforcement, 3D printed parts are durable, stable, and can protect components susceptible to shock and impact better than any other engineering-grade filament. With a properly designed and 3D printed NylonG part, your creations will stand up to the toughest environments and meet the highest standards.

Rigid Protection for 3D Printed Components

NylonG filament is ideal for reinforcing the design of a wide range of creations, especially those that need impact and shock resistance. High tensile strength, high dimensional accuracy, and low-warp during 3D printing mean your 3D prints come out looking great while maximizing the longevity of your projects.

Start Your Adventure with NylonG

While NylonG is an engineering-grade filament made for technical 3D printing, it's also ready for your home 3D printer. Low-warp, improved tensile strength, high impact resistance and it's ready to go right off the print bed with little to no post-processing. It's additive manufacturing in your own home, so you can enjoy more 3D printing and fewer failed prints.