Choosing the Best E3D Hotend // Comparison Guide

Industry leader E3D has many variants of their top-seller E3D V6 hotend. Take a look at where each one shines and which might be best for you.

What really put E3D on the map was their purpose built 3D printer hotends. These were designed for 3D printing’s needs and not repurposed from other hardware components. Now, there are multiple variations on the sixth version of their hotend (the E3D V6), each intended for increasingly higher flow rates to really get filament flowing. Almost every hotend is 1.75mm or 2.85mm filament compatible and is offered in both direct drive and bowden configurations.

Let's jump into it-

E3D Hotends at a Glance

- Dual Extrusion

- While there isn’t a dual-extrusion hotend available, with a custom designed mount you can mount two E3D V6s side-by-side to achieve the same thing.

- Cooling

- All of E3Ds current hotend options rely on air-cooling using a small fan to push cool air onto the heatsinks.

- Maximum Temperature

- With a plated copper heater block, a NozzleX, and PT100 temperature sensor the E3D V6 or Volcano can reach 500°C with ease.

- Flow Rate

- The SuperVolcano lives up to its name and can extrude out a 1.4mm nozzle without flinching.

- Upgrades

- E3D is built on modularity, so every hotend can be swapped and upgraded as you grow your 3D printing skills.

- Filament Size Compatibility

- Within the V6 ecosystem, with the right heatsink, heartbreak, and nozzle any hotend can use 1.75mm or 2.85mm filament.

- Direct-Drive or Bowden

- Any E3D hotend is bowden compatible, but even those without a dedicated direct drive option can use a small length of PTFE tubing to connect your extruder to the hotend and make it direct-drive.

- Mounting Options

- The V6 platform mostly uses a groove-mount to hold the heatsink in place, but some use threaded heatsinks to clamp onto its mount.

Dual Extrusion

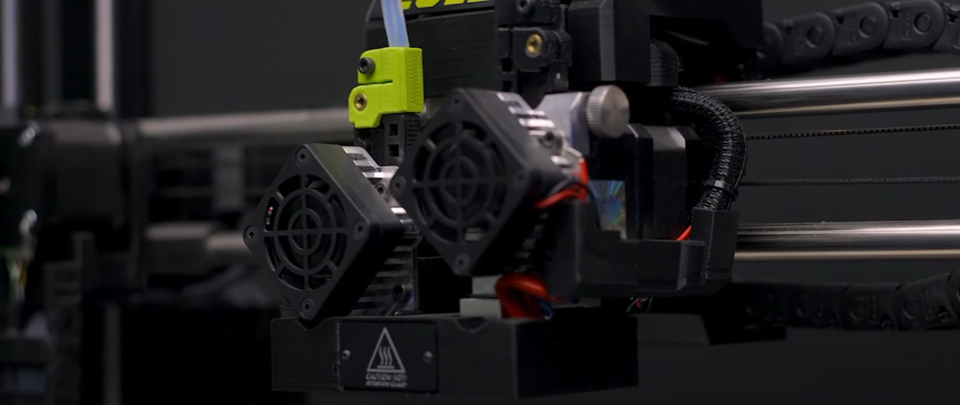

If you need to have dual-extrusion functionality, you have two options: design or download a mounting system that utilizes any of E3Ds single-extruder options, like two Titan Aeros side-by-side just like the Lulzbot TAZ PRO’s toolhead, or use some system like the E3D ToolChanger to change out the printhead to one loaded with a different material or color. Otherwise, there aren’t any hotends designed specifically for dual-extrusion, and instead you will just have a printhead with two hotends on it.

Cooling

E3D hotends are air-cooled; they use a small fan to push cool air past a heatsink to keep the temperatures low and prevent heat from creeping away from the heater block. When a hotend is installed in an enclosure, to keep temperatures around the printed part high and avoid any material complications, you prevent any cool air from being blown on the heatsink and instead only have hot air to move around. This is problematic for certain materials and can cause a jam as heat creeps up past the heat break and into the heatsink with nothing to cool it down. E3D has a liquid cooled option: the Titan Aqua, an extruder/hotend combo that uses a redesigned heatsink to circulate a liquid coolant from a pump located outside the enclosure, where it is continually cooled. We will get into the details of the Titan Aqua in another video.

Maximum Temperature

More often than not, an E3D hotend’s maximum temperature is determined by its sensor, not its construction. The standard cartridge thermistor included in each hotend kit has a maximum working temperature of 300°C, and if exceeded begins to rapidly become unreliable or even fails altogether. In this case a PT100 or thermocouple replacement can allow you to reach up to 500°C if the hotend’s materials don’t melt. Generally a plated-copper heater block for the V6, Volcano, SuperVolcano, or is the limit of any hardware changes needed to reach such a high temperature. However, the Lite6 has a maximum temperature of 240°C as it is a PTFE-lined hotend and PTFE noxiously degrades at temperatures higher than that, and no hardware changes can be made to affect that other than a new hotend altogether.

Flow Rate

In order to extrude more filament without overworking the extruder motor, you need to lengthen the melt zone of the hotend. In the case of E3D, that means making the heater block taller and to give the filament more time to heat up and leave the nozzle at the necessary temperature. The E3D Volcano was the first introduction to higher flowrates with a heater block almost double the length of the original V6. As you might expect, the SuperVolcano is two and a half times as long as a Volcano and can extrude filament out of a 1.4mm nozzle in 1mm layers; laying an absurd amount of filament and turning a spool faster than you’ve ever seen.

Upgrades

E3D hotends are incredibly modular, which means at any point in time you can swap out every component for a newer replacement with more capabilities, or just for general maintenance. Try a gold-anodized heatsink for some extra flair or a titanium heartbreak for supreme thermal control. There are even kits available to upgrade from a V6 heater block to a Volcano or SuperVolcano without having to change anything other than the heater block and nozzle (and fan ducts to keep the layer cooling fan of your printer aimed at your parts and not the longer block).

Filament Sizes

At this point in time, 2.85mm filament is finding less and less options available for mods and upgrades, yet E3D continues to support with many 2.85mm components. There are only three parts per hotend necessary to print with a specific filament diameter: the heatsink, heatbreak, and nozzle. Among E3D’s offerings, the V6, Volcano, and SuperVolcano support 2.85mm filament or 1.75mm filament (depending on the aforementioned components), whereas the rest of their hotends only support 1.75mm filament.

Direct-Drive or Bowden

Depending on the nature of your 3D printing, it can be advantageous to have your hotend mounted directly to your extruder (which is referred to as “direct-drive” for better filament control at the cost of increased mass on the print head. Alternatively, sacrificing a little control (and needing more retraction) you can move the extruding to the frame and have a long PTFE tube connect the extruder to your hotend (this technique is called “bowden”) to lower the moving mass of the printhead. The heatsink used for the E3D V6, Volcano, and SuperVolcano is suited for direct-drive or bowden, as long as you are working with the right version. The 1.75mm heatsink is used for both direct or bowden configurations, but the 2.85mm heatsink is specifically direct-drive or bowden, not both, so you will need to choose wisely prior to ordering.

Mounting Options

When it comes to hotends, there are many different ways you can mount one to your printhead in a reliably stiff way. For the most part, E3D utilizes a groove-mount setup where the heatsink slides into a mount, printed or otherwise, that cradles the top of the heatsink in place. A slight modification of the V6 heatsink exists in the form of the threaded heatsink that can be inserted through the mount with a nut that clamps down from above, giving a much more secure fit than the groove-mount option. You will want to note though that the threaded heatsink can only be used for bowden configurations, as most extruders rely on the groove mount geometry to mount a hotend to them.

E3D is virtually synonymous with 3D printer hotends thanks to their wide offerings and regular updates to the platform. From simple and reliable to complex and capable, every E3D hotend excels at the tasks they were designed for whether or not it’s just PLA printing or needs engineering-grade PEEK. To learn more and to order your own E3D hotend, check out the collection here.

Request a Quote

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day. Alternatively, you can always feel free to give us a call at +1 (800) 613-4290 or email sales@matterhackers.com.